Shearing Drawing

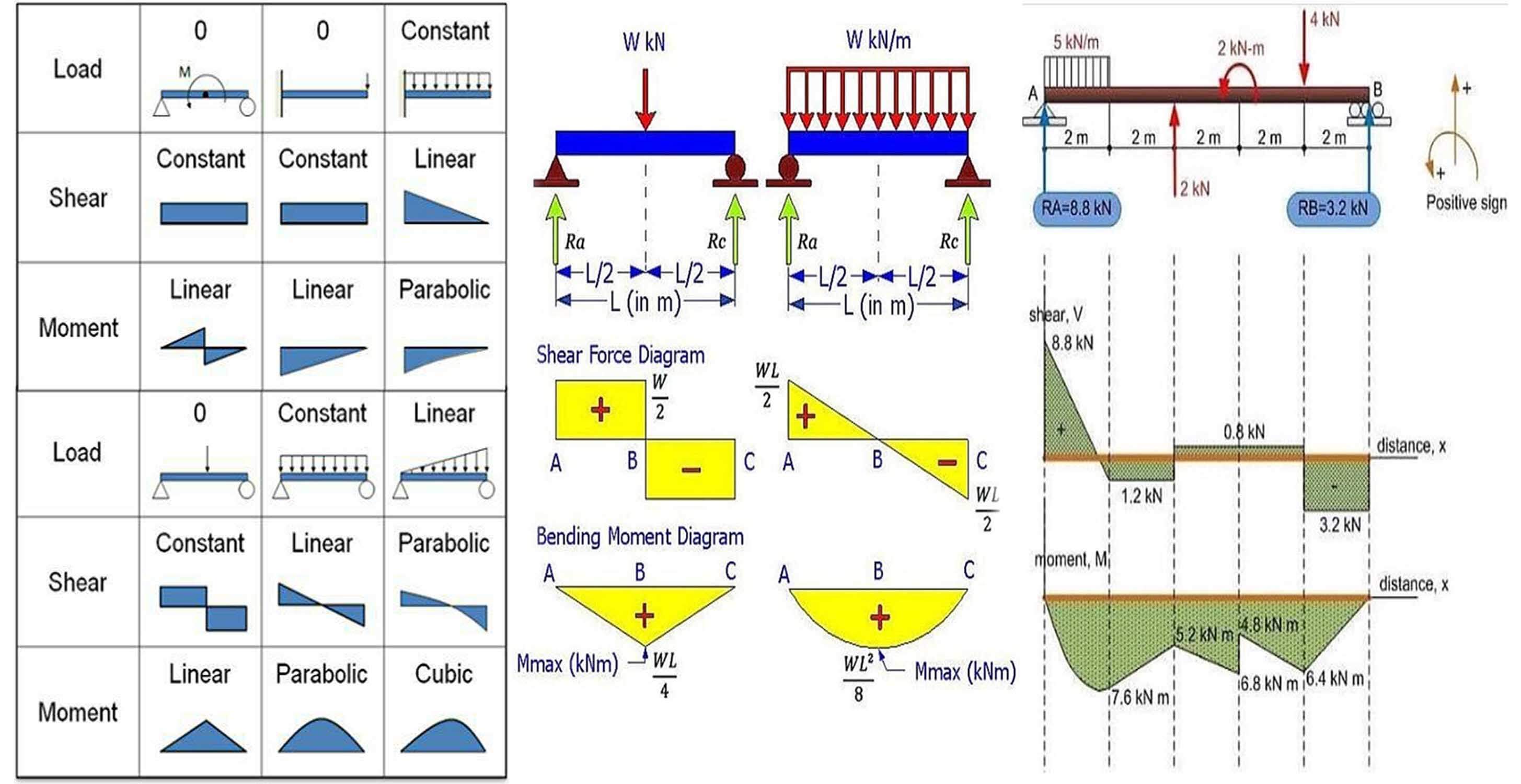

Shearing Drawing - The shearing operation is cut in a straight line across a strip, sheet, or bar. Sheet metal forming and sheet metal operations. Web this tutorial shows how to draw the shear and moment diagrams (i.e., internal force diagrams) for beam structures, an essential topic for students in engineering mechanics or structural. Beams are long and slender structural elements, differing from truss elements in that they are called on to support transverse as well as axial loads. Web sheet metal shearing, a process fundamental to our manufacturing at shengen and designed to cut straight metal stock on flat surfaces, is an essential part of the production. Shear walls resist wind loads. They resist horizontal loads such as wind and seismic loads and transfer these loads down to the foundation. Web the common types of sheet metal operations are shearing, blanking, punching, piercing, trimming, drawing, embossing, bending, and squeezing operations. In strict technical terms, the process of “shearing” involves the use of straight cutting bladesorm of sheet metal or plates, however, rods can also be sheared. Web sheet metal forming, or sheet metal fabrication is the process of using metal sheets to form sheet metal components. The shearing operation is cut in a straight line across a strip, sheet, or bar. Strictly speaking, if the cutting blades are straight the process is called shearing; Web shearing, also known as die cutting, is a process that cuts stock without the formation of chips or the use of burning or melting. Bending and shearing stresses •bending •shearing •punching. 6.2.4 tips & plot shapes. Web •deep drawing •spinning •stripping •wrinkle bulging; These points include locations where concentrated loads, point loads, and distributed loads are applied. Hydraulic shearing machine instruction manual. Bending, punching, shearing, and hydroforming among others. We use a machine with two sharp blades for this process. Technically shearing does not involve shaping by plastic deformation, but it is a critical process in sheet metal working operations and should be understood along with metal forming processes. This is achieved by forming and cutting sheets into the required shapes and forms using a variety of processes such. They resist horizontal loads such as wind and seismic loads and transfer these loads down to the foundation. Blanking, piercing, roll slitting, and trimming[4]. Technically shearing does not involve shaping by plastic deformation, but it is a critical process in sheet metal working operations and should be understood along with metal forming processes. Web shearing, also known as die cutting,. Web shearing, also known as die cutting, is a process that cuts stock without the formation of chips or the use of burning or melting. It is similar to sliding the layers in one direction to change the shape of the 2d object.it is an ideal technique to change the shape of an existing object in a two dimensional plane.. The shearing operation is cut in a straight line across a strip, sheet, or bar. It leaves a lean edge on the piece of metal is sheared or cut. These points include locations where concentrated loads, point loads, and distributed loads are applied. Forming under tensile stress •stretch forming •stretching •expanding; This is achieved by forming and cutting sheets into. Beams are long and slender structural elements, differing from truss elements in that they are called on to support transverse as well as axial loads. Metal forming processes are also classified into two types according to the type of workpiece. 6.2.4 tips & plot shapes. Web the common types of sheet metal operations are shearing, blanking, punching, piercing, trimming, drawing,. Shear walls resist wind loads. It is similar to sliding the layers in one direction to change the shape of the 2d object.it is an ideal technique to change the shape of an existing object in a two dimensional plane. Forming under tensile stress •stretch forming •stretching •expanding; Web shear walls stabilize a building. Hydraulic shearing machine instruction manual. It leaves a lean edge on the piece of metal that is sheared or cut. ** hydraulic shears circuit diagram. Web this tutorial shows how to draw the shear and moment diagrams (i.e., internal force diagrams) for beam structures, an essential topic for students in engineering mechanics or structural. Calculate the shear forces at key points along the beam. It. The shearing operation is cut in a straight line across a strip, sheet, or bar. Bending, punching, shearing, and hydroforming among others. 6.2.4 tips & plot shapes. Web shearing is the cutting of the work piece, this would include punching holes. Web in this video i explain how to draw shear and moment diagrams. Web shearing, also known as die cutting, is a process that cuts stock without the formation of chips or the use of burning or melting. Web drawing the shear diagram. Hydraulic shearing machine maintenance procedures. Web shearing is the cutting of the work piece, this would include punching holes. The shearing operation is cut in a straight line across a strip, sheet, or bar. Web shearing (piercing, blanking, punching, trimming, notching, nibbling, and perforating), bending, drawing, embossing, coining, etc., which mainly involves sheet metal, are called sheet metal operations. Sheet metal forming and sheet metal operations. Bending, punching, shearing, and hydroforming among others. Strictly speaking, if the cutting blades are straight the process is called shearing; Web the common types of sheet metal operations are shearing, blanking, punching, piercing, trimming, drawing, embossing, bending, and squeezing operations. 6.2.2 distributed loads & shear/moment diagrams. Massachusetts institute of technology via mit opencourseware. Web shearing is a stamping process that separates sheet or coil material along a straight or curved line using specialized shearing equipment. It leaves a lean edge on the piece of metal that is sheared or cut. Web •deep drawing •spinning •stripping •wrinkle bulging; Calculate the shear forces at key points along the beam.

Sheep shearing antique drawing hires stock photography and images Alamy

Male farmer shearing sheep flat vector character. Wool production

Farmworker shearing sheep etching Royalty Free Vector Image

SHEARING PROCESS SHEARING MECHANISM SHEAR FORCE SHEAR STRENGTH

Farmer shearing sheep flat vector character. Wool production. Livestock

How to draw shear and moment diagrams YouTube

How to Shear a Sheep in 20 Steps Sheep farm, Sheep drawing, Sheep

Sheep Shearing, Australia, 1886.artist Drawing by Print Collector

Learn How To Draw Shear Force And Bending Moment Diagrams Engineering

Man shearing sheep flat Royalty Free Vector Image

We Use A Machine With Two Sharp Blades For This Process.

Shear Walls Resist Wind Loads.

Web Blanking Is A Cutting Process In Which A Piece Of Sheet Metal Is Removed From A Larger Piece Of Stock By Applying A Great Enough Shearing Force.in This Process, The Piece Removed, Called The Blank, Is Not Scrap But Rather The Desired Part.blanking Can Be Used To Cutout Parts In Almost Any 2D Shape, But Is Most Commonly Used To Cut Workpieces With Simple.

6.2.4 Tips & Plot Shapes.

Related Post: