Fillet Symbol In Engineering Drawing

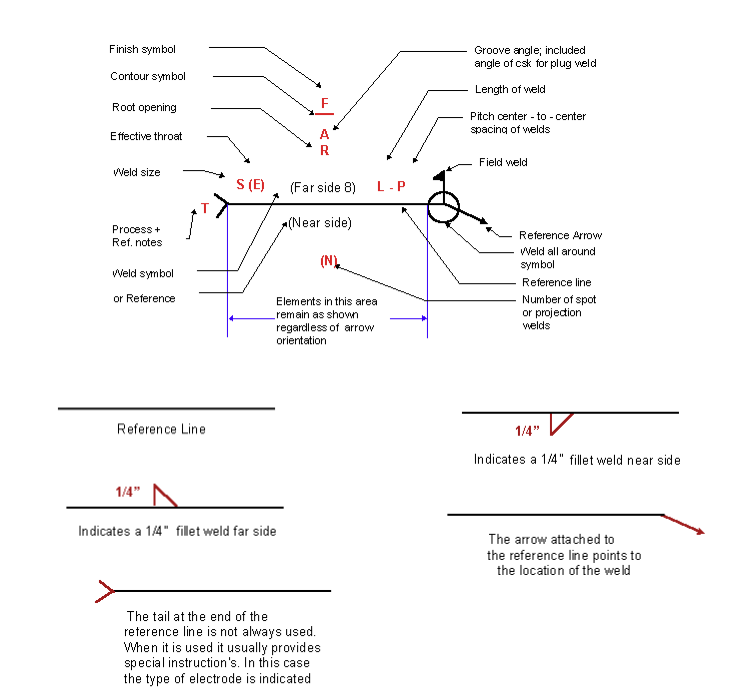

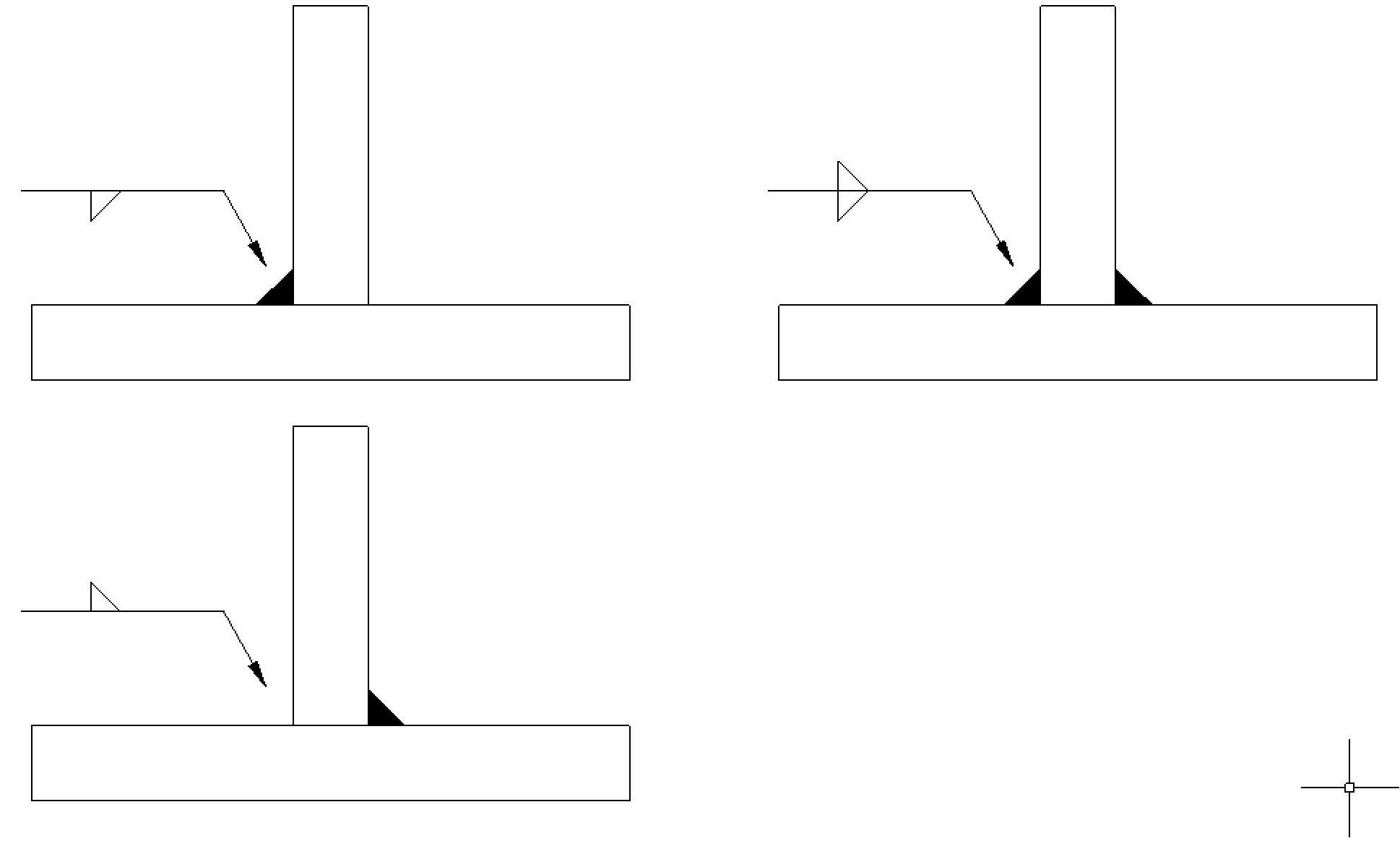

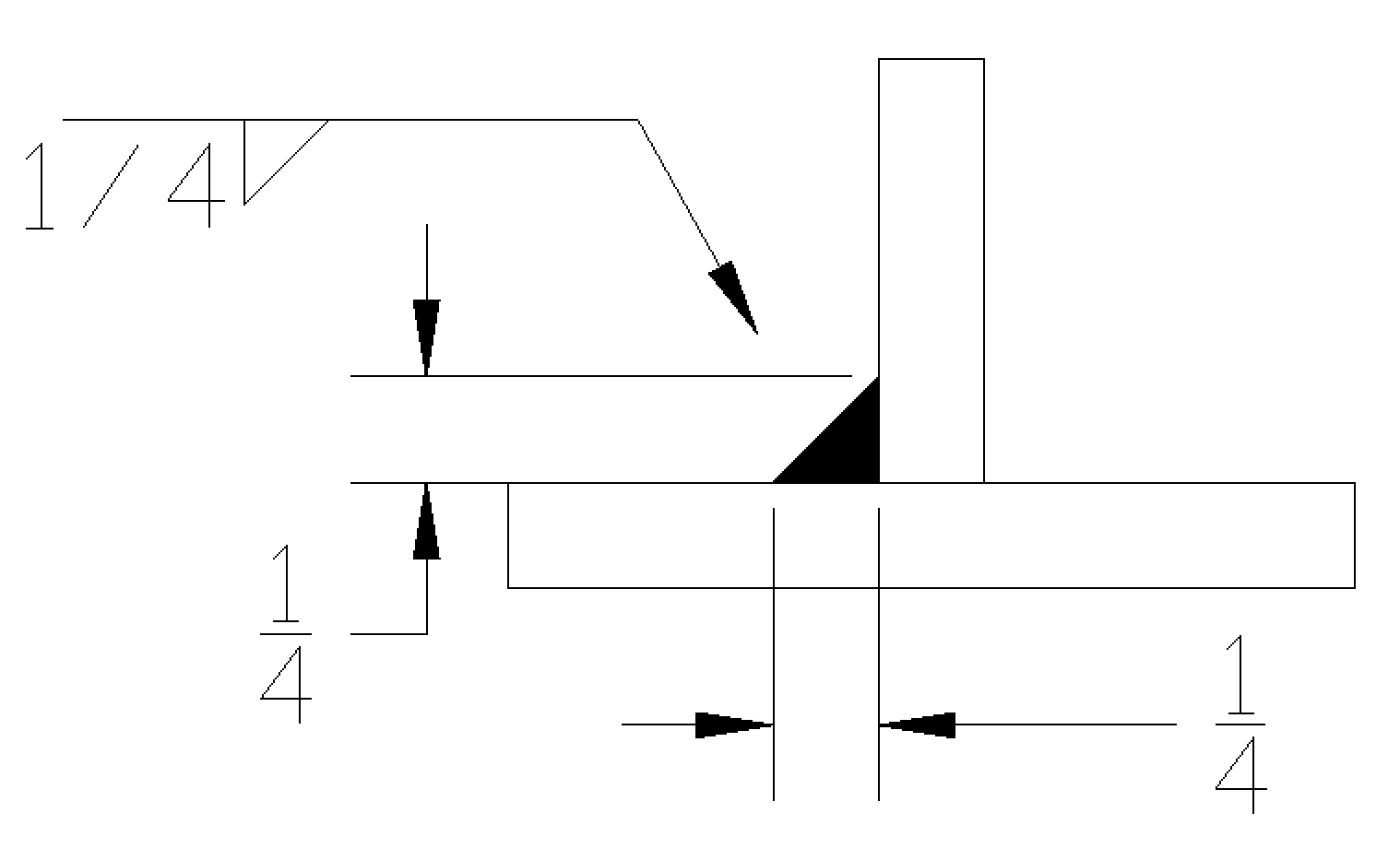

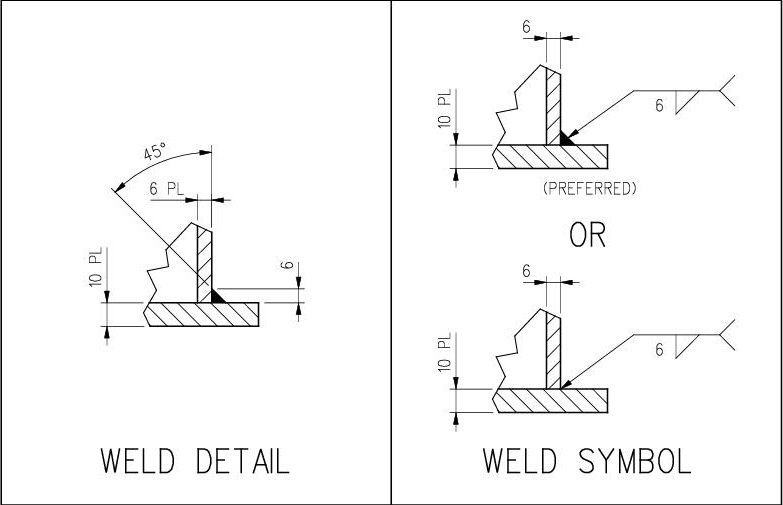

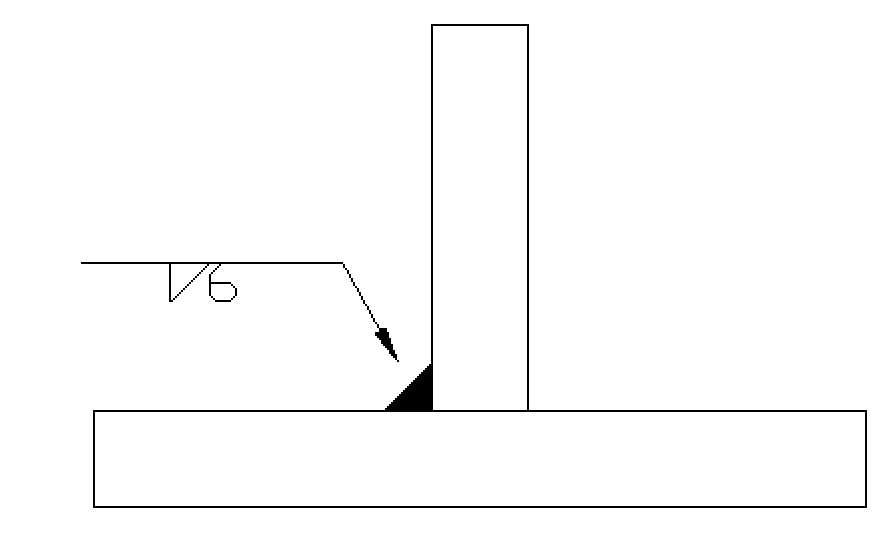

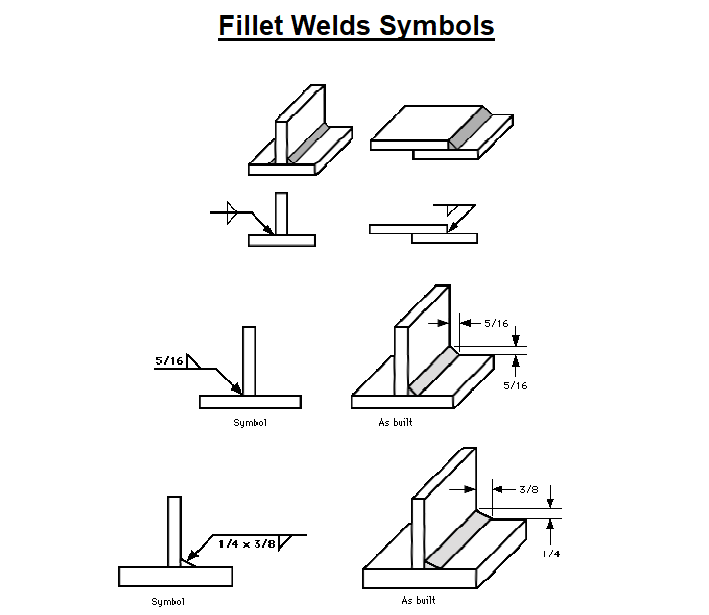

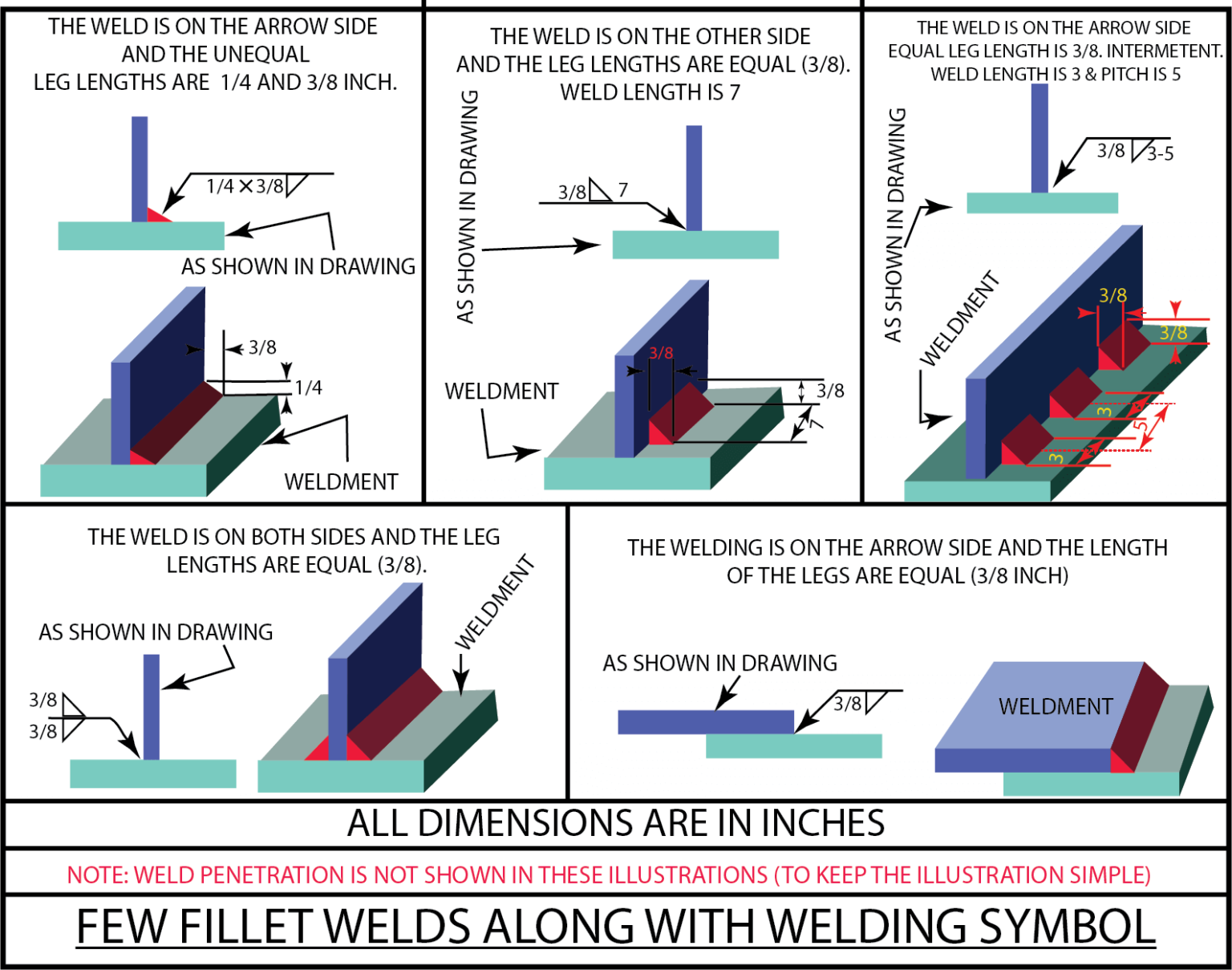

Fillet Symbol In Engineering Drawing - An interior or exterior corner, with an angle or type of bevel, is called a chamfer. These welds can be applied on varying angles but this would be the most prominent. Are used to give details about the weld type, weld size, & other supportive information such as welding process, surface finish requirements, etc. Web for fillet welds, numbers to the left of the symbol indicate the design throat thickness, leg length (leg size), or both design throat thickness and leg length requirements. Web engineering drawing abbreviations and symbols are used to communicate and detail the characteristics of an engineering drawing. For the sake of graphical clarity, the drawings below do not show the penetration of the weld metal. It involves depositing a weld along the edge of the metal, creating a triangular fillet shape. This weld is used when the joint has two members coming together to form an intersection of commonly 90 degrees. Web a fillet weld symbol can be used with an arrow side (below reference line) other side (above reference line) significance or on both sides (both sides of the reference line.) when a fillet weld is required on both sides. Fillet welds are one of the most common weld types in the industry. Figure 8 gives examples of symbols used in different standards. These welds can be applied on varying angles but this would be the most prominent. Web fillet weld symbols explained. Web engineering drawing abbreviations and symbols are used to communicate and detail the characteristics of an engineering drawing. When identification of the weld process is required as part of the. Generally, but not in all cases, fillet welds are of equal legs. Apart from all the lines in the structure, you would also see different weld symbols. Web drawing of weld symbols. These welds can be applied on varying angles but this would be the most prominent. Web the weld_symbol_standard configuration option in the detail module enables you to set. Fillet welds are some of the most common welds you’ll encounter as a welder. Different types of basic weld symbols make up the fabrication or engineering drawings. When identification of the weld process is required as part of the weld symbol the relevant weld process code is listed in bs en iso 4063. Web welding symbols and drawings are essential. Different types of basic weld symbols make up the fabrication or engineering drawings. These welds can be applied on varying angles but this would be the most prominent. You are more than likely going to come across welds on engineering and fabrication drawings. A fillet weld symbol can be used with an arrow side. Fillets and rounds are specified using. Fillets and rounds are specified using the “radius” symbol, “r”. Web fillet weld symbols explained. A fillet is indicated on a drawing in the same way as a round, illustrated in figure 2, with a dimension that includes the radius symbol and radius length. Web a fillet weld symbol can be used with an arrow side (below reference line) other. Web what are the most commonly used engineering drawing symbols and their meanings? In the case of fillet welding, the drawings and symbols and their correct interpretations are critical to learning the basics of fillet welding. The british standard for weld symbols was bs en 22553 which has been superseded by bs en iso 2553:2019. Web the most important symbols. The dimension specifying the leg size of a fillet weld is placed to the left of the fillet weld symbol, and on the same side of the reference line. Engineering drawing symbols play a vital role in communication among engineers and other stakeholders involved in the design and construction process. Web basic weld symbols. Web a fillet weld symbol can. Web drawing of weld symbols. The aws defines a fillet weld as: Web the fillet weld symbol can be represented with an arrow pointing up or down, indicating the location of the weld, either above or below the reference line. • grooved—square, bevel, v, u, and j. Fillet welds are one of the most common weld types in the industry. Different types of basic weld symbols make up the fabrication or engineering drawings. Generally, but not in all cases, fillet welds are of equal legs. Web basic weld symbols. An interior or exterior corner, with an angle or type of bevel, is called a chamfer. Fillet welds are one of the most common weld types in the industry. Web for fillet welds, numbers to the left of the symbol indicate the design throat thickness, leg length (leg size), or both design throat thickness and leg length requirements. Fillet welds are some of the most common welds you’ll encounter as a welder. The radius value is given next to the symbol. These welds can be applied on varying angles. In the case of fillet welding, the drawings and symbols and their correct interpretations are critical to learning the basics of fillet welding. Learn more about fillets and rounds in the video below: Web fillet weld symbols explained. The following weld symbols are supported in iso: This weld is used when the joint has two members coming together to form an intersection of commonly 90 degrees. Web the weld_symbol_standard configuration option in the detail module enables you to set the symbol support for your drawings. A fillet weld symbol can be used with an arrow. Gb/t 5185 designation of metal welding and brazing methods in drawings; Apart from all the lines in the structure, you would also see different weld symbols. The dimension specifying the leg size of a fillet weld is placed to the left of the fillet weld symbol, and on the same side of the reference line. Fillets and rounds are specified using the “radius” symbol, “r”. Figure 8 gives examples of symbols used in different standards. It is applicable to both metal fusion welding and resistance welding. For the sake of graphical clarity, the drawings below do not show the penetration of the weld metal. Web the most important symbols that you do have to memorize are the fillet weld symbol and the groove weld symbol. Web in mechanical engineering, a fillet is a rounding of an interior or exterior corner of a part designed in cad.

Understanding the Welding Symbols in Engineering Drawings Safe Work

1.6 Fillet Weld Symbols Workforce LibreTexts

Fillet Weld Symbols Interpretation of Metal Fab Drawings

Dimensioning of welds Engineering Drawing Basics

Welding Symbols Chart An Explanation of the Basics (with Pictures

[SOLVED] In engineering drawing, the welding symbol used for fillet

Fillet Weld Symbols On Drawings

Understanding the Welding Symbols in Engineering Drawings Safe Work

Engineering Drawing Weld Symbols

Welding Symbols Guide to Reading Weld Symbols

Web For Fillet Welds, Numbers To The Left Of The Symbol Indicate The Design Throat Thickness, Leg Length (Leg Size), Or Both Design Throat Thickness And Leg Length Requirements.

Web Basic Weld Symbols.

Web Drawing Of Weld Symbols.

The Vertical Side Of This Triangle Showing The Fillet Weld Symbol Is Always Placed On The Left Side Of The Drawing Reader/ Viewer As Shown In The Below Figure.

Related Post: