Engineering Drawing Meaning

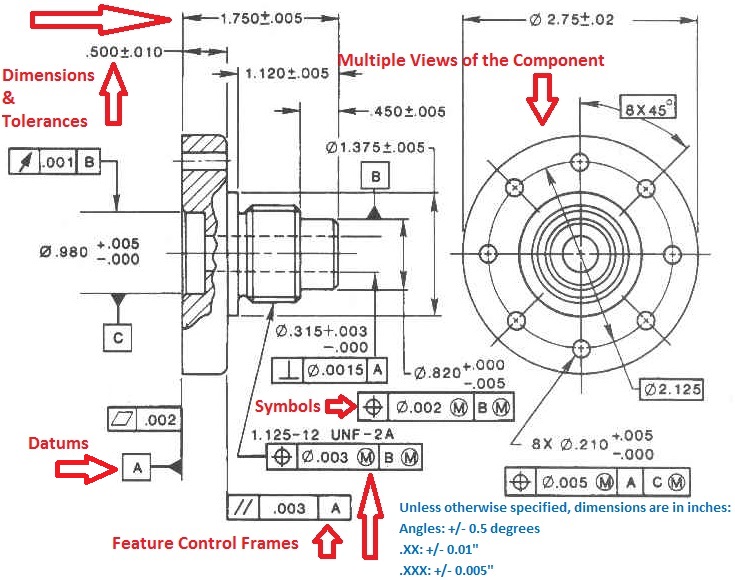

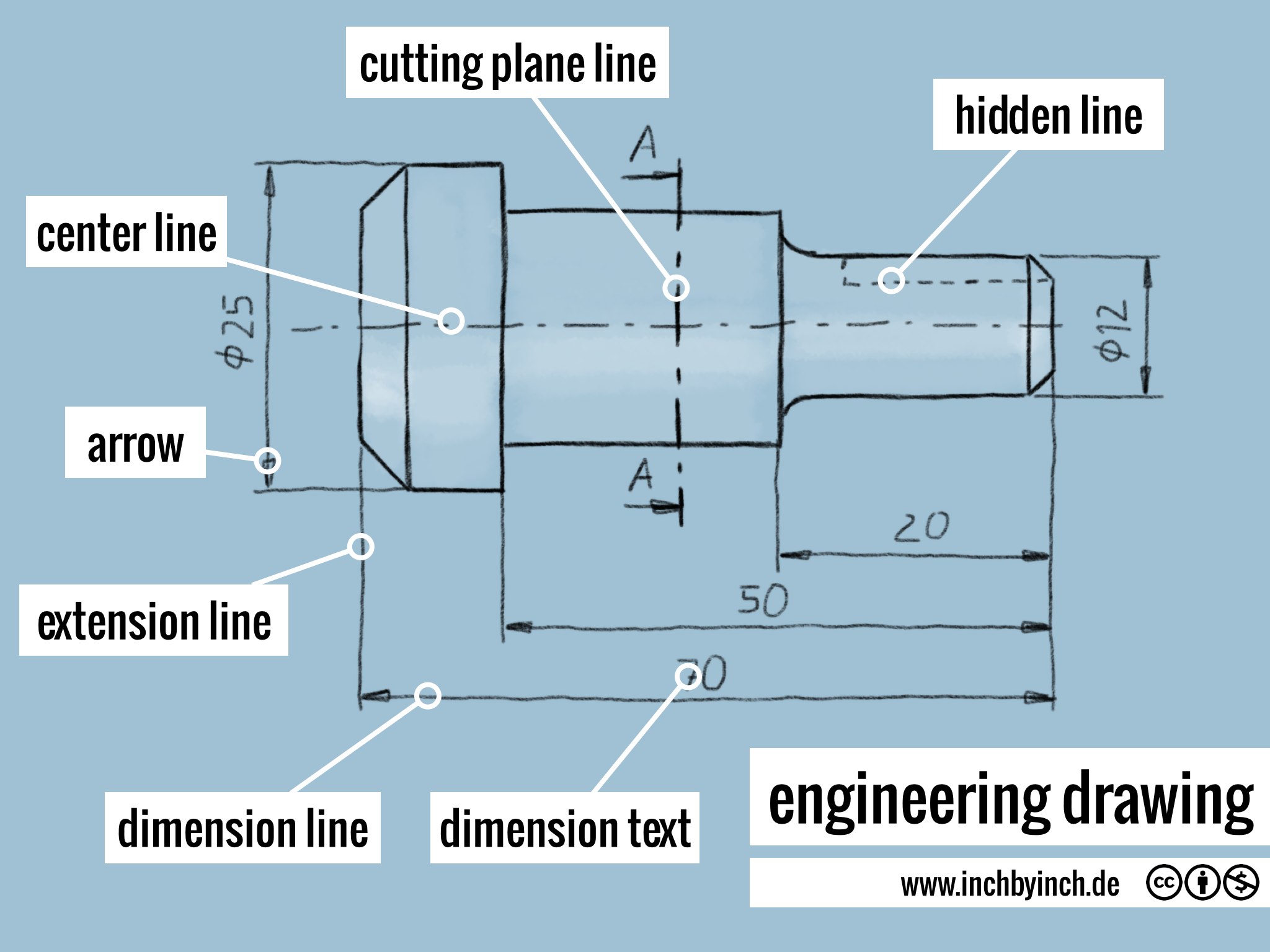

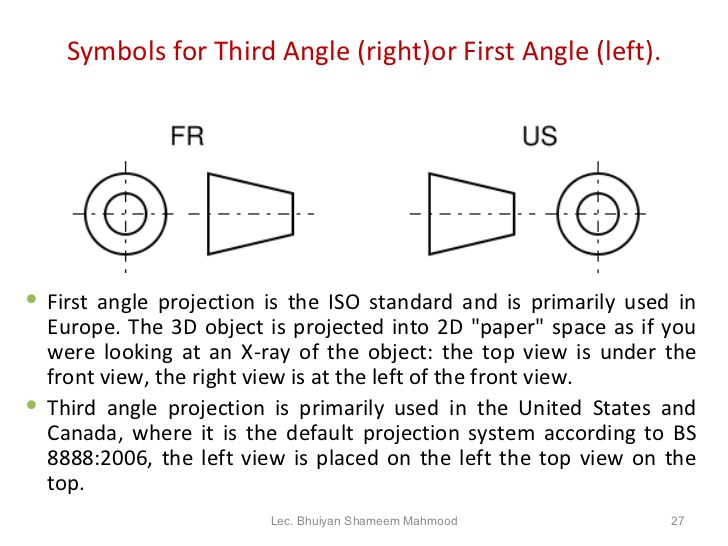

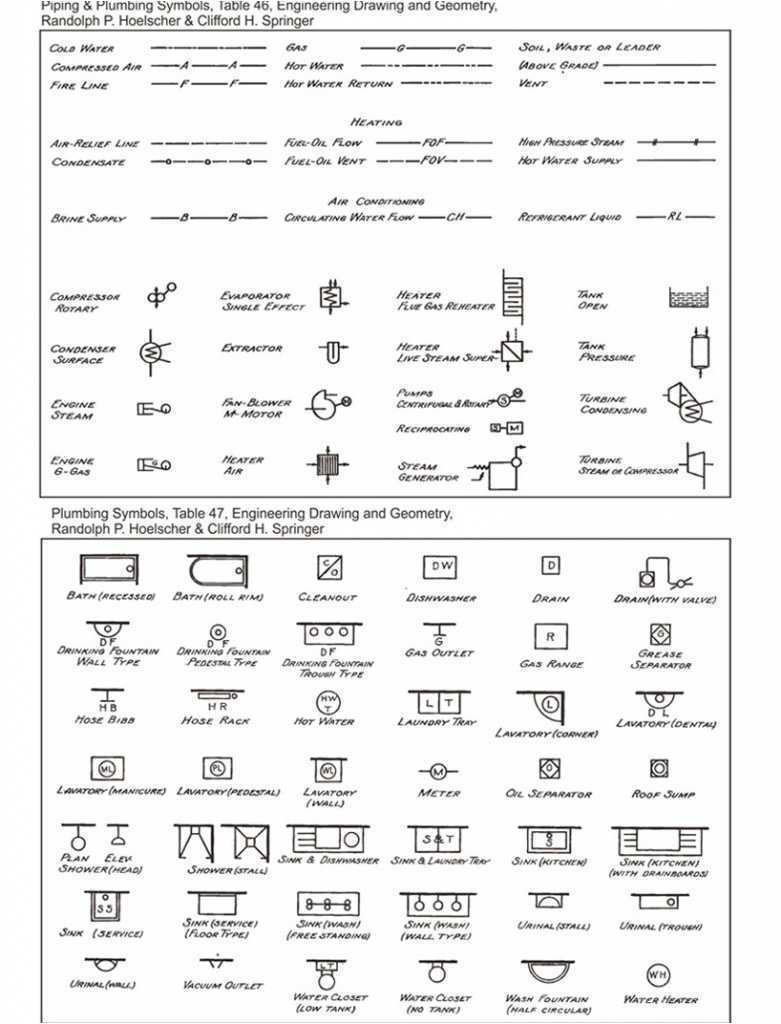

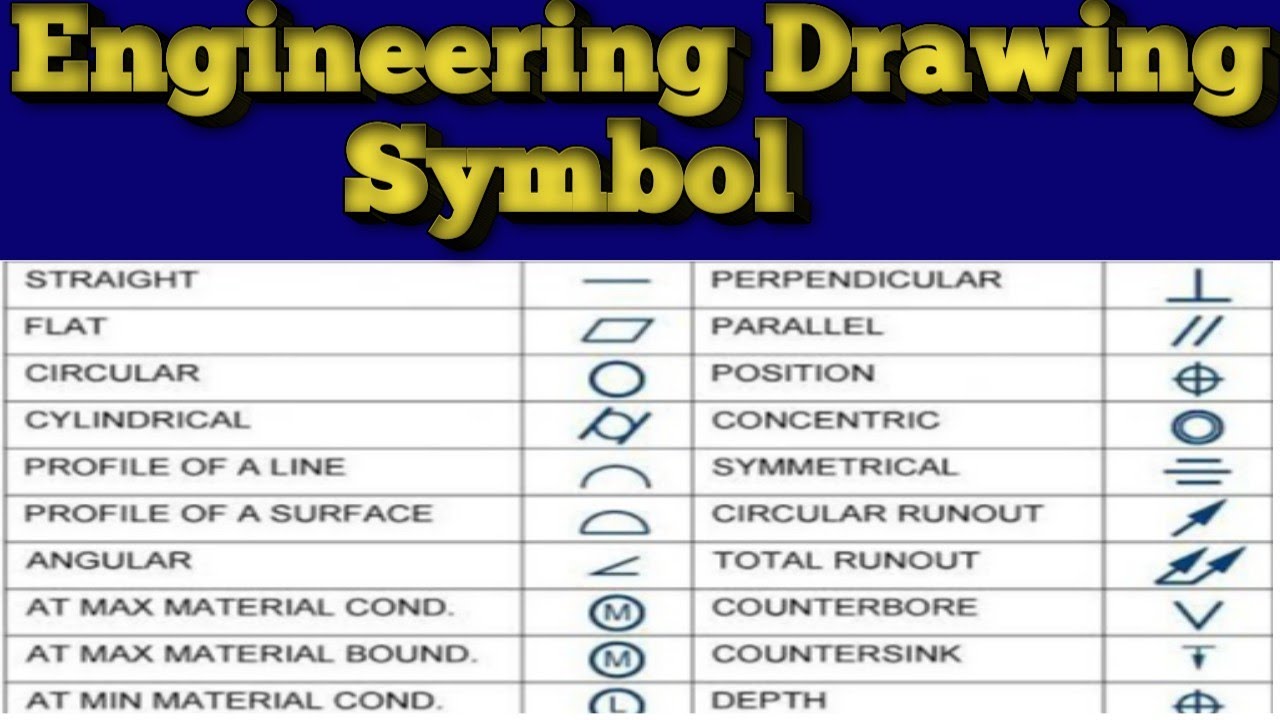

Engineering Drawing Meaning - This standard defines the types of engineering drawings most frequently used to establish engineering requirements. The purpose is to convey all the information necessary for manufacturing a product or a part. We will treat “sketching” and “drawing” as one. Web an engineering drawing, rather than an image, is used to illustrate the size and shape of a product and can include details such as appropriate variants, load limit s, materials, and any other information that may aid in a full understanding of the product. What the difference is between counterbore and countersink holes. 1.3 importance in various fields like mechanical engineering, civil engineering, etc. A convenient guide for geometric dimensioning and tolerancing (gd&t) symbols at your fingertips. Web just as an architectural drawing or blueprint shows you how to construct a building, an engineering drawing shows you how to manufacture a specific item or product. The engineering drawings prepared by gsfc design personnel or contractors on gsfc The different types of holes used in machining. 1.2 historical background and evolution. The symbols used for each hole and how they are shown on engineering drawings. Web engineering drawing is a specialized form of communication that uses a strict set of symbols, standards, and perspectives to depict mechanical, electrical, or structural designs. This is a complete guide to the types of holes found in machining. 1.4 types. What the difference is between counterbore and countersink holes. Click on the links below to learn more about each gd&t symbol or concept, and be sure to download the free wall chart for a quick reference when at your desk or on the shop floor. How to read symbols in an engineering drawing? These drawings are essentially the blueprints or. Web every phase of engineering design starting from concept illustration all the way to the manufacturing phase. 1.4 types of engineering drawing: These symbols are standardized and universally recognized, allowing engineers from different disciplines and countries to understand each other's drawings without ambiguity. Various symbols and abbreviations in engineering drawings give you information about the dimensions, design, and materials used.. Web the purpose of this guide is to give you the basics of engineering sketching and drawing. Engineering drawings are also known as mechanical drawings, manufacturing blueprints and drawings. What the difference is between counterbore and countersink holes. The purpose is to convey all the information necessary for manufacturing a product or a part. Web engineering drawings are the industry's. A convenient guide for geometric dimensioning and tolerancing (gd&t) symbols at your fingertips. The video below covers the fundamentals, including the different types of views, first and third angle projection methods, dimensioning, tolerancing, best practices when creating drawings. These symbols are standardized and universally recognized, allowing engineers from different disciplines and countries to understand each other's drawings without ambiguity. Web. You can think about engineering drawing as a fundamental piece of information in mechanical engineering; Web engineering drawings, also known as mechanical drawings, manufacturing blueprints, drawings, etc., are technical drawings that show the shape, structure, dimensions, tolerances, accuracy, and other requirements of a part in the form of a plan. We will treat “sketching” and “drawing” as one. Engineering drawings. How each type of hole is used in engineering. “drawing” usually means using drawing instruments, from compasses to computers to bring precision to the drawings. Web an engineering drawing is a subcategory of technical drawings. It is more than simply a drawing, it is a graphical language that communicates ideas and information. A common use is to specify the geometry. Web dimensioning practice once the shape of a part is defined with an orthographic drawing (i.e., in projections), the size information is added in the form of dimensions. Here we collected the standard engineering drawing abbreviations and symbols to provide help for users. These symbols are standardized and universally recognized, allowing engineers from different disciplines and countries to understand each. How each type of hole is used in engineering. In this guide you’ll learn: The video below covers the fundamentals, including the different types of views, first and third angle projection methods, dimensioning, tolerancing, best practices when creating drawings. Web gd&t symbols | gd&t basics. Why abbreviations and symbols are needed for engineering drawing? This makes understanding the drawings simple with little to no personal interpretation possibilities. Web an engineering drawing is a subcategory of technical drawings that show the shape, structure, dimensions, tolerances, accuracy and other requirements needed to manufacture a product or part. The purpose is to convey all the information necessary for manufacturing a product or a part. Work with runsom. “drawing” usually means using drawing instruments, from compasses to computers to bring precision to the drawings. Web gd&t symbols | gd&t basics. 1.2 historical background and evolution. Hence the art of reading and creating the drawing is fundamental knowledge for any mechanical engineer. Web engineering drawings are the industry's means of communicating detailed and accurate information on how to fabricate, assemble, troubleshoot, repair, and operate a piece of equipment or a system. Web an engineering drawing is a subcategory of technical drawings that show the shape, structure, dimensions, tolerances, accuracy and other requirements needed to manufacture a product or part. In this guide you’ll learn: Why abbreviations and symbols are needed for engineering drawing? Web an engineering drawing, rather than an image, is used to illustrate the size and shape of a product and can include details such as appropriate variants, load limit s, materials, and any other information that may aid in a full understanding of the product. A common use is to specify the geometry necessary for the construction of a component and is called a detail drawing. Web engineering drawing abbreviations and symbols are used to communicate and detail the characteristics of an engineering drawing. These symbols are standardized and universally recognized, allowing engineers from different disciplines and countries to understand each other's drawings without ambiguity. Web engineering drawings, also known as mechanical drawings, manufacturing blueprints, drawings, etc., are technical drawings that show the shape, structure, dimensions, tolerances, accuracy, and other requirements of a part in the form of a plan. An engineering (or technical) drawing is a graphical representation of a part, assembly, system, or structure and it can be produced using freehand, mechanical tools, or computer methods. How to read symbols in an engineering drawing? How each type of hole is used in engineering.

Engineering Drawings & GD&T For the Quality Engineer

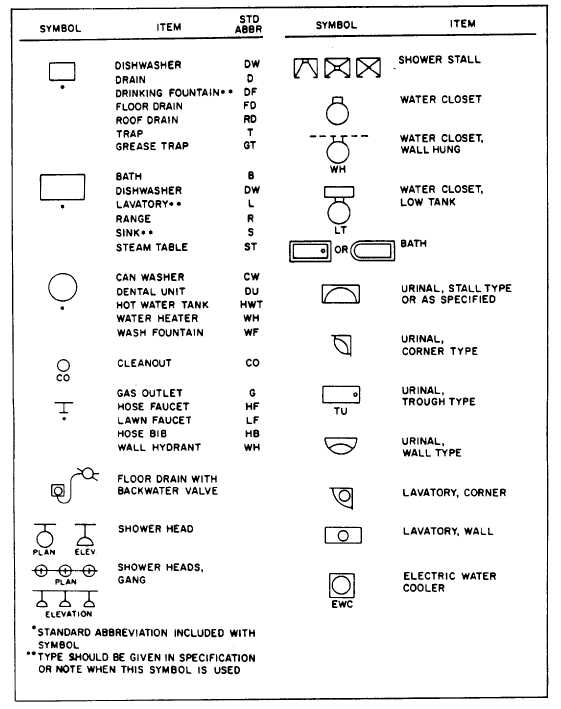

Civil Engineering Drawing Symbols And Their Meanings at PaintingValley

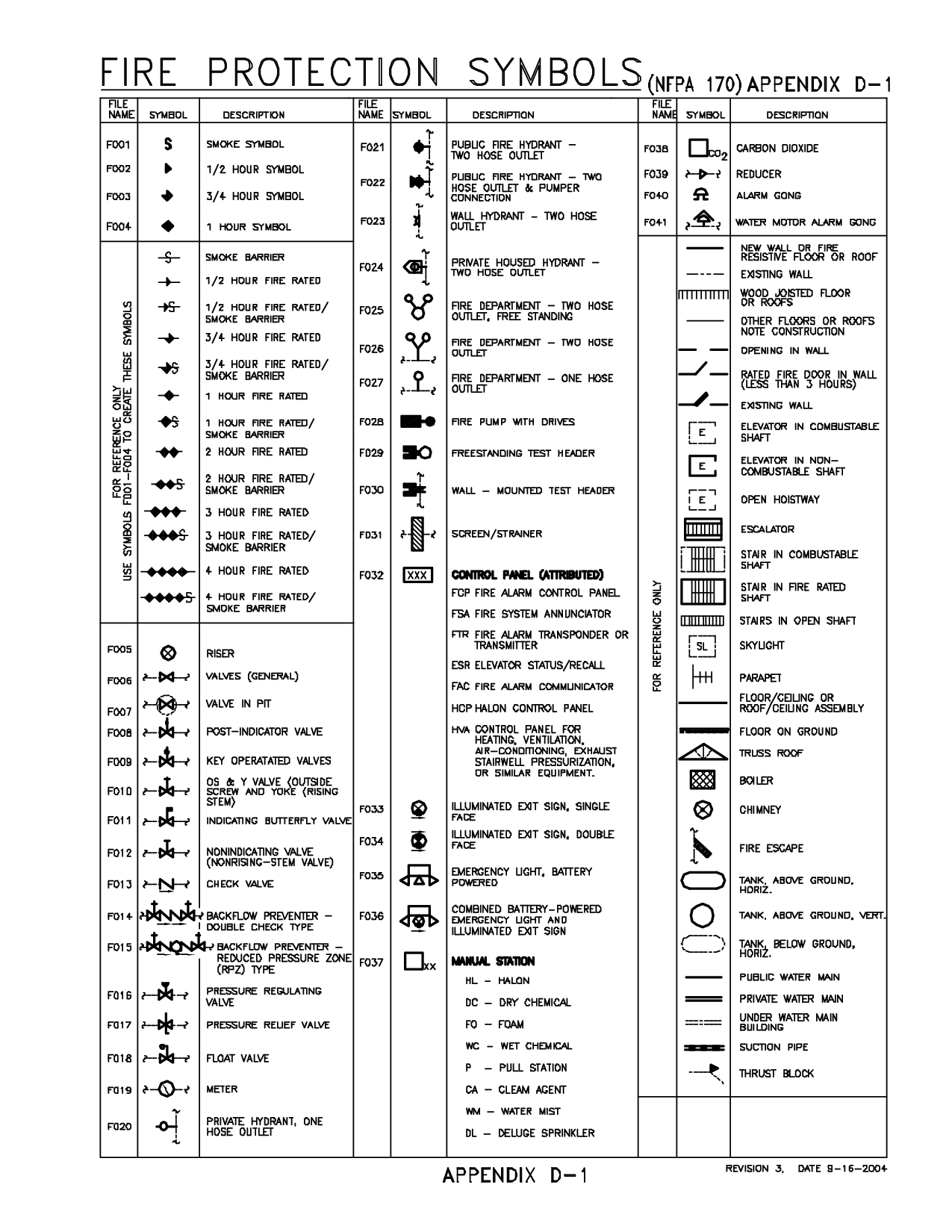

Engineering Drawing Symbols And Their Meanings Pdf at PaintingValley

Engineering Drawing Symbols And Their Meanings Pdf at PaintingValley

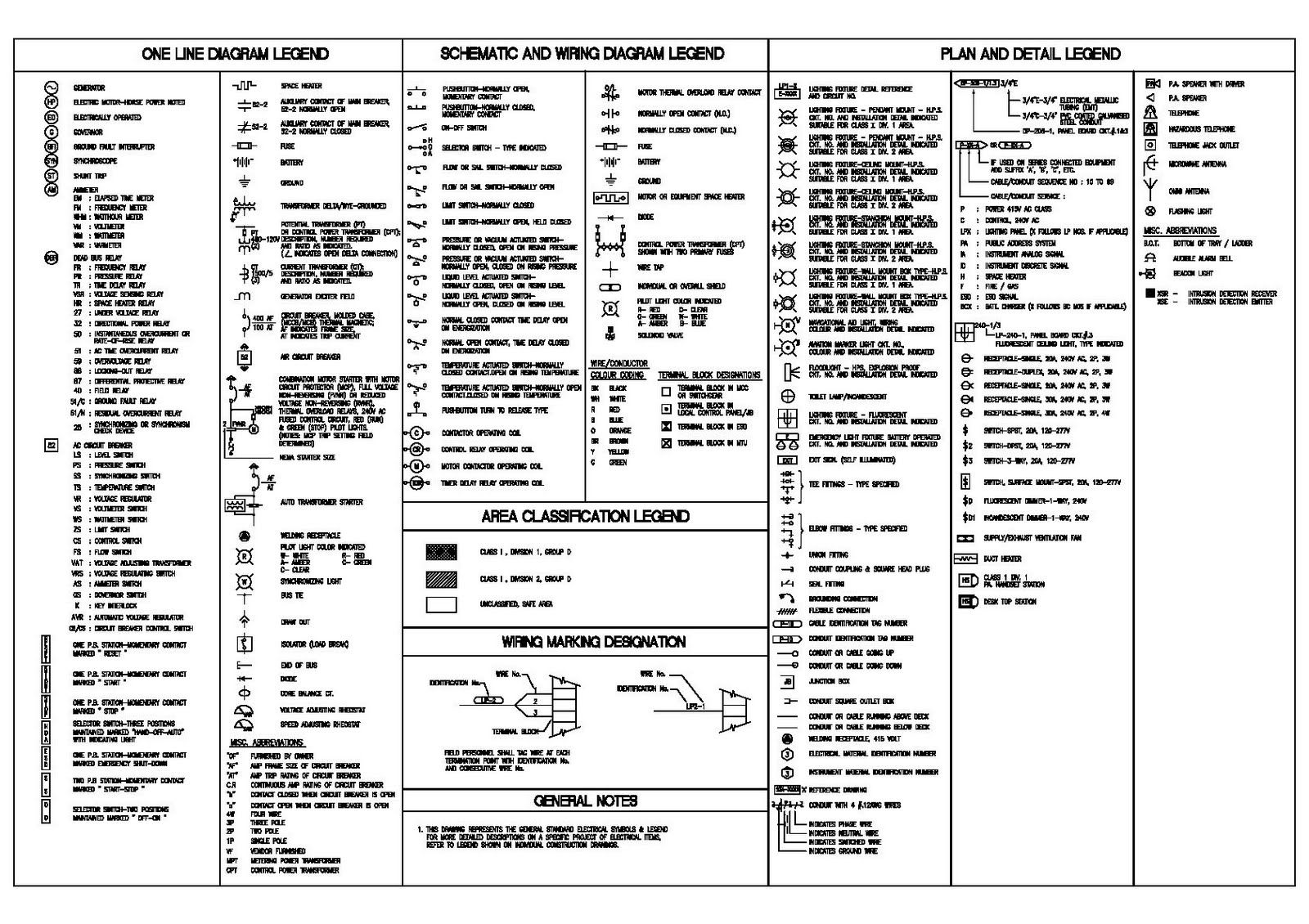

INCH Technical English engineering drawing

Engineering Drawing Definition, Types and Reasons for Studying

Engineering Drawing Symbols And Their Meanings Pdf at PaintingValley

Engineering Drawing Symbols And Their Meanings Pdf at PaintingValley

Mechanical Engineering Drawing and Design, Everything You Need To Know

Technical Drawing Symbols And Their Meanings Design Talk

This Standard Defines The Types Of Engineering Drawings Most Frequently Used To Establish Engineering Requirements.

Drawings For Specialized Engineering Disciplines (E.g., Marine, Civil, Construction, Optics, Etc.) Are Not Included In This Standard.

A Convenient Guide For Geometric Dimensioning And Tolerancing (Gd&T) Symbols At Your Fingertips.

Click On The Links Below To Learn More About Each Gd&T Symbol Or Concept, And Be Sure To Download The Free Wall Chart For A Quick Reference When At Your Desk Or On The Shop Floor.

Related Post: