Dimensioning In Engineering Drawing

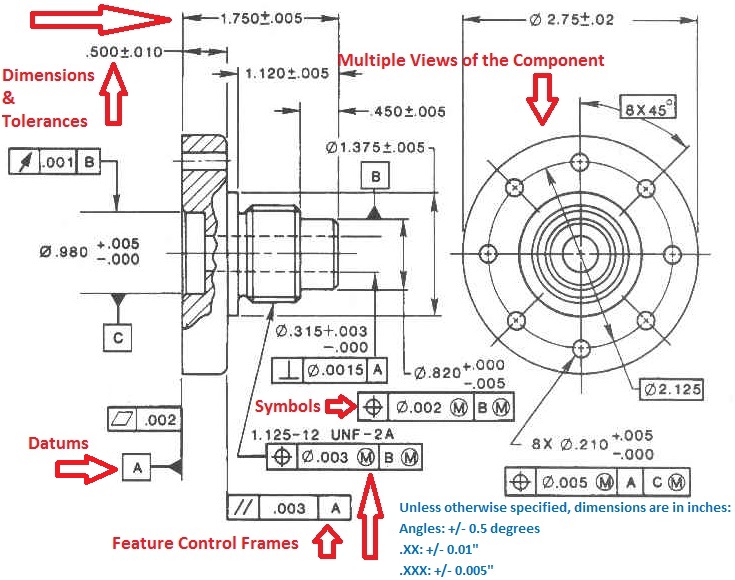

Dimensioning In Engineering Drawing - Using gd&t results in a more accurate design, larger tolerances for less important design features, and cost savings for manufacturing. Engineering drawings and sketches need to display simplicity and uniformity, and they must be executed with speed. This occurs when multiple tolerance errors are added together. The angle begins as the midpoint of the 3” long dimension. The exact shape of the part or assembly is shown by the different views in the drawing sheet. Dimensions and notations must be placed on the sketch where they can be clearly and easily read. Web geometric dimensioning and tolerancing is a set of rules and gd&t symbols used on a drawing to communicate the intent of a design, focusing on the function of the part. Gd&t is a way of describing the dimensions and tolerances that’s different from traditional coordinate measurement plus/minus tolerancing. Double dimensioning of a feature is not permitted. Web dimensioning a drawing is about adding dimension, notes, & lines to a drawing. 3.2 lines, angles, and dimensions. Do not leave any size, shape, or material in doubt. The purpose of engineering drawings is to convey objective facts, whereas artistic drawings convey emotion or artistic sensitivity in some way. Correct values must be given. Double dimensioning of a feature is not permitted. Using gd&t results in a more accurate design, larger tolerances for less important design features, and cost savings for manufacturing. Web every dimension must have an associated tolerance, and that tolerance must be clearly shown on the drawing. A complete set of dimensions will permit only one interpretation needed to construct the part. Fundamentally, engineers design a part with perfect. Before an object can be built, complete information about both the size and shape of the object must be available. In other words, with the use of dimensioning technics on the engineering drawings, we define the physical boundaries of the component, like the size and location of the different features. Web 3.1 geometric shapes and their significance. A complete set. To avoid confusion and the possibility of error, no dimension should be repeated twice on any sketch or drawing. Engineering drawings and sketches need to display simplicity and uniformity, and they must be executed with speed. 3.2 lines, angles, and dimensions. Some methods of dimensioning a drawing can produce an accumulated error. The dimensions are 3” long, 2 1/8” wide,. Web what is dimensioning in engineering drawing? The angle begins as the midpoint of the 3” long dimension. The drilled through hole is ∅5/8”. 4.3 common mistakes and how to avoid them. Web learn everything you need to know about dimensioning engineering drawings. The base is ½” x 1 ½” square. Dimensioning is vital in the engineering industry as it ensures that the final product meets the required standards and specifications. Web dimensioning is the process of defining the size, form and location of geometric features and components on an engineering drawing. 4.2 tips for sketching, dimensioning, and detailing. Web five basic types. Web geometric dimensioning and tolerancing is a set of rules and gd&t symbols used on a drawing to communicate the intent of a design, focusing on the function of the part. Web dimensioning a drawing is about adding dimension, notes, & lines to a drawing. What you’ll learn in this post: Our comprehensive guide covers techniques, standards, and best practices. Web five basic types of dimensioning in engineering drawing. Proper use of gd&t can improve quality and reduce the time and cost of delivery. A complete set of dimensions will permit only one interpretation needed to construct the part. Dimensioning should follow these guidelines. The base is ½” x 1 ½” square. Web geometric dimensioning and tolerancing is a set of rules and gd&t symbols used on a drawing to communicate the intent of a design, focusing on the function of the part. The base is ½” x 1 ½” square. This occurs when multiple tolerance errors are added together. Double dimensioning of a feature is not permitted. Web every dimension must. Dimension elements dimensioning a drawing also identifies the tolerance (or accuracy) required for each dimension. Web dimensioning a drawing is about adding dimension, notes, & lines to a drawing. Double dimensioning of a feature is not permitted. Gd&t is a way of describing the dimensions and tolerances that’s different from traditional coordinate measurement plus/minus tolerancing. The cylinder is 1” ∅. Fundamentally, engineers design a part with perfect geometry in cad, but manufactured parts are never perfect. The cylinder is 1” ∅. Web every dimension must have an associated tolerance, and that tolerance must be clearly shown on the drawing. Do not leave any size, shape, or material in doubt. Web what is dimensioning in engineering drawing? Dimensions should be placed in the view which most clearly describes the feature being dimensioned. Web systems of dimensioning and tolerancing. Some methods of dimensioning a drawing can produce an accumulated error. A complete set of dimensions will permit only one interpretation needed to construct the part. The exact shape of the part or assembly is shown by the different views in the drawing sheet. Web 3.1 geometric shapes and their significance. Before an object can be built, complete information about both the size and shape of the object must be available. Dimension elements dimensioning a drawing also identifies the tolerance (or accuracy) required for each dimension. Engineering drawings and sketches need to display simplicity and uniformity, and they must be executed with speed. Proper use of gd&t can improve quality and reduce the time and cost of delivery. Dimensions and notations must be placed on the sketch where they can be clearly and easily read.

Types Of Dimensions In Engineering Drawing at GetDrawings Free download

Types Of Dimensions In Engineering Drawing at GetDrawings Free download

![Dimensioning Its Types, System, Principles. [A Comprehensive Guide].](https://civilseek.com/wp-content/uploads/2018/10/dimensioning.jpg)

Dimensioning Its Types, System, Principles. [A Comprehensive Guide].

1.4aPlacing of Dimension Systems in Engineering Drawing Aligned and

Types Of Dimensions In Engineering Drawing at GetDrawings Free download

Dimensioning and its role in drafting and design

engineeringdrawing Dimensioning used in Engineering Drawing YouTube

System of dimensioning, Dimensioning methods in Engineering Drawing

Types Of Dimensions In Engineering Drawing at GetDrawings Free download

GENERAL RULES OF DIMENSIONING in Engineering Drawing YouTube

4.3 Common Mistakes And How To Avoid Them.

Engineering Drawing Of A Machine Tool Part.

4.2 Tips For Sketching, Dimensioning, And Detailing.

The Drilled Through Hole Is ∅5/8”.

Related Post: