Deep Drawing Metal

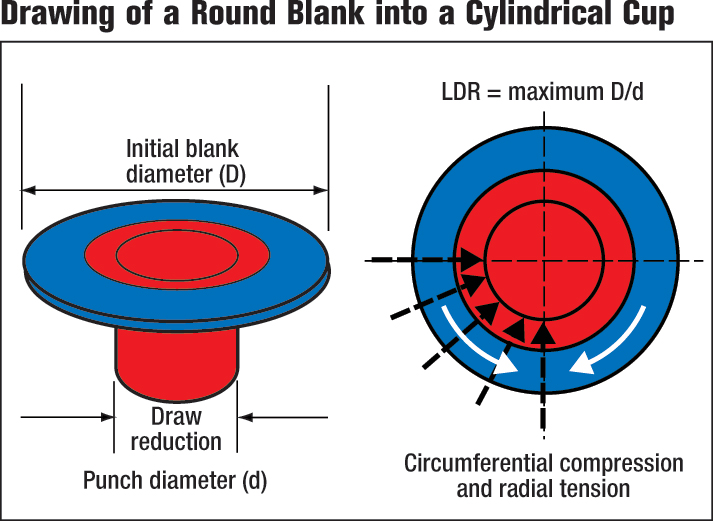

Deep Drawing Metal - Press speed (ram speed) draw radii; This technique involves applying a force to the metal sheet, causing it to stretch and form over the contours of a die, thus creating a deep, cup. Parts produced by metal stamping can range from 0.25 inches in diameter or smaller, to very large aircraft, automotive and appliance parts. Web deep drawing is a metal forming process used to create hollow, seamless parts with a depth greater than their diameter by drawing a sheet metal blank into a forming die with a punch. Key elements in deep drawing. Web the following are key elements affecting metal flow, and each of them should be considered when designing, building, or troubleshooting deep drawing stamping dies: And, the material’s versatility in operation makes that point pretty clear. Web precision metal deep drawn stamping is used to make practically any part and product out of sheet metal. Web hudson technologies is a leading u.s. Web deep drawing is a special process in sheet metal forming which is capable of forming many metallic parts and structures, and it covers a wide range of applications in packaging, automotive and aerospace industries. Perhaps one of the biggest misconceptions about deep drawing is that the metal is stretched into the part geometry. Two main factors will cause the punch in deep drawing to draw the metal into the die cavity, rather than shearing it. Web deep drawing is a metal forming process used to create hollow, seamless parts with a depth greater than. Web prospect machine products deep draw metal stamping. And, the material’s versatility in operation makes that point pretty clear. Drawing can be defined as a forming process in which the flow of metal into a cavity or over a post is controlled. Web deep drawing is a metal forming process used to create hollow, seamless parts with a depth greater. Web what is deep drawn metal stamping? Metal stamping and die design: 3 applications and industries benefiting from deep drawing. Web deep drawing is a special process in sheet metal forming which is capable of forming many metallic parts and structures, and it covers a wide range of applications in packaging, automotive and aerospace industries. Web appropriate materials include aluminum. Metal stamping and die design: This process is the combination of metal forming process and sheet metal process. Web appropriate materials include aluminum alloys, brass, copper and copper alloys, titanium, cold rolled low carbon sheet steel, and some stainless steels. 1 what is sheet metal drawing? 2.2 factors influencing the deep drawing process. Web precision metal deep drawn stamping is used to make practically any part and product out of sheet metal. Metal stamping and die design: Parts produced by metal stamping can range from 0.25 inches in diameter or smaller, to very large aircraft, automotive and appliance parts. 2 deep drawing sheet metal : 1.1 what are the key factors affecting sheet. And, the material’s versatility in operation makes that point pretty clear. Web what is deep drawing? Web deep drawing of irregularly shaped panels constitutes one of the most complex metalforming operations. And it’s starting to go global with more features. Key elements in deep drawing. Metal stamping and die design: Metal stamping and die design: Web metal drawing is a metalworking process by which metal is stretched and formed using tensile force. Deep drawn stamping is even used to make locks, appliances, and lighting components. Web deep drawing of irregularly shaped panels constitutes one of the most complex metalforming operations. Metal stamping and die design: Web metal drawing is a metalworking process by which metal is stretched and formed using tensile force. Perhaps one of the biggest misconceptions about deep drawing is that the metal is stretched into the part geometry. The deep drawing process is often a combination of stretch forming and deep drawing. However, when broken down into. Web deep drawing is the manufacturing process of forming sheet metal stock, called blanks, into geometrical or irregular shapes that are more than half their diameters in depth. Stamping is a general term that encompasses a broad range of metal forming capabilities and industrial uses. And it’s starting to go global with more features. Has been producing precision deep drawn. Metal stamping and die design: 2.1 the deep drawing process. Web precision metal deep drawn stamping is used to make practically any part and product out of sheet metal. Web deep drawing is a metal forming process used to create hollow, seamless parts with a depth greater than their diameter by drawing a sheet metal blank into a forming die. Every deep draw metal stamping process starts with planning the part. 2 deep drawing sheet metal : And it’s starting to go global with more features. The process is typically performed cold, which is done to ensure accurate tolerances, better grain structure and surface finish, as well as improved material properties. Web for one deep drawing or the last deep drawing in multi deep drawing, 4 types of metal stamping process. Web deep drawn sheet metal: Here at pmp, we tailor our deep drawing expertise in our metal forming technology to our customers’ needs & best practices. Two main factors will cause the punch in deep drawing to draw the metal into the die cavity, rather than shearing it. Charles richter specializes in everything from spheres and cylinders, cans and cups, to housings and housewares. Metal stamping and die design: Manufacturer of deep drawn metal enclosures, or cases, and stampings, including metal diaphragms. Metal stamping and die design: Web deep drawing is a special process in sheet metal forming which is capable of forming many metallic parts and structures, and it covers a wide range of applications in packaging, automotive and aerospace industries. Web appropriate materials include aluminum alloys, brass, copper and copper alloys, titanium, cold rolled low carbon sheet steel, and some stainless steels. Web deep drawing is a sheet metal forming process that involves complex material flow and force distributions. Has been producing precision deep drawn enclosures and shallow drawn metal components for over 70 years.

Deep Drawing from A to Z MetalForming Magazine Article

03_04_P1 Important Process Parameters in Sheet Metal Drawing or Deep

Deep Drawing Of Sheet Metal

Deep Drawn Methodology and Its Benefits

Deep drawing of sheet metal

Deep Drawing Metal Fabrication Service ABT Metals Manufacturing

Deep Drawing New England Metalform, Inc., Precision Metal Stamped

Deep Draw Metal Stampings & Formed Parts Hudson Technologies

What is Deep Drawing? Process, Diagram, Advantages & Applications

What Is Deep Drawing ? Working Of Deep Drawing Sheet Metal Processes

The Deep Drawing Process Is Often A Combination Of Stretch Forming And Deep Drawing.

Web What Is Deep Drawing?

Web As Specialists In Deep Draw Technologies, National Manufacturing Co., Inc.

Metal Is One Of The Most Flexible Materials In The World At The Moment.

Related Post: