Deep Draw Stampings

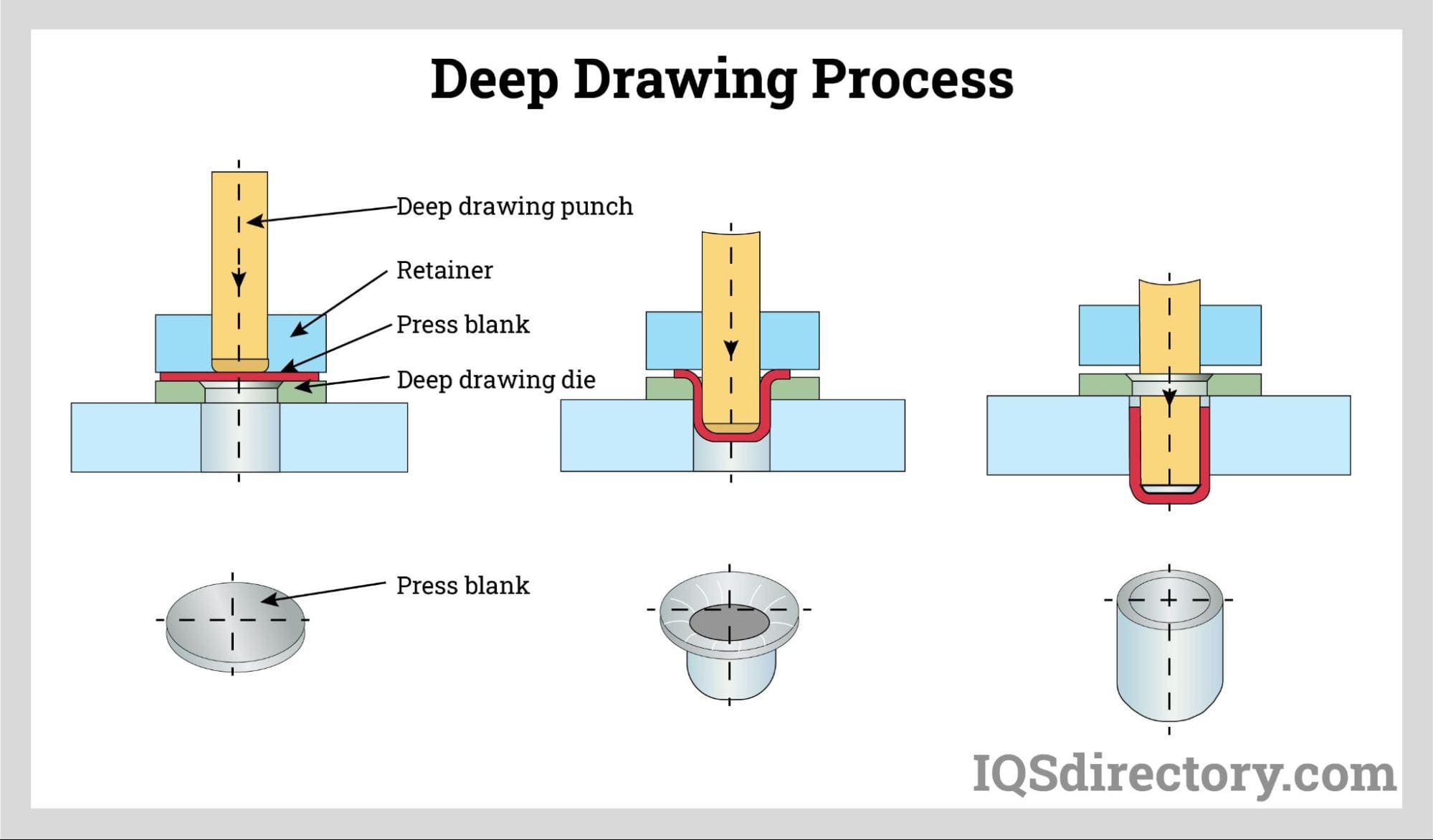

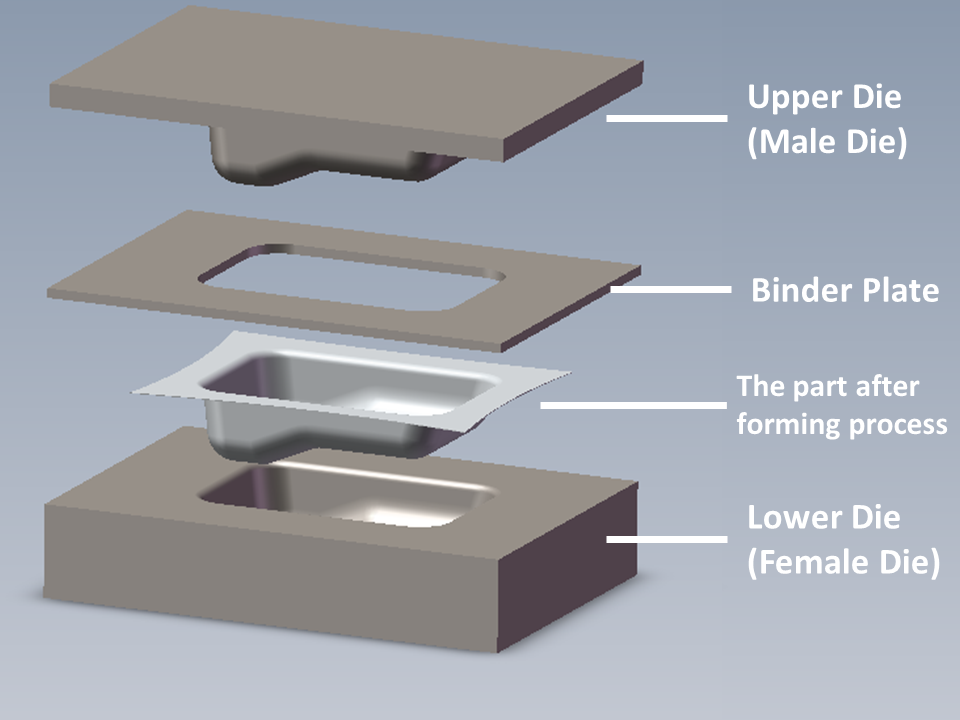

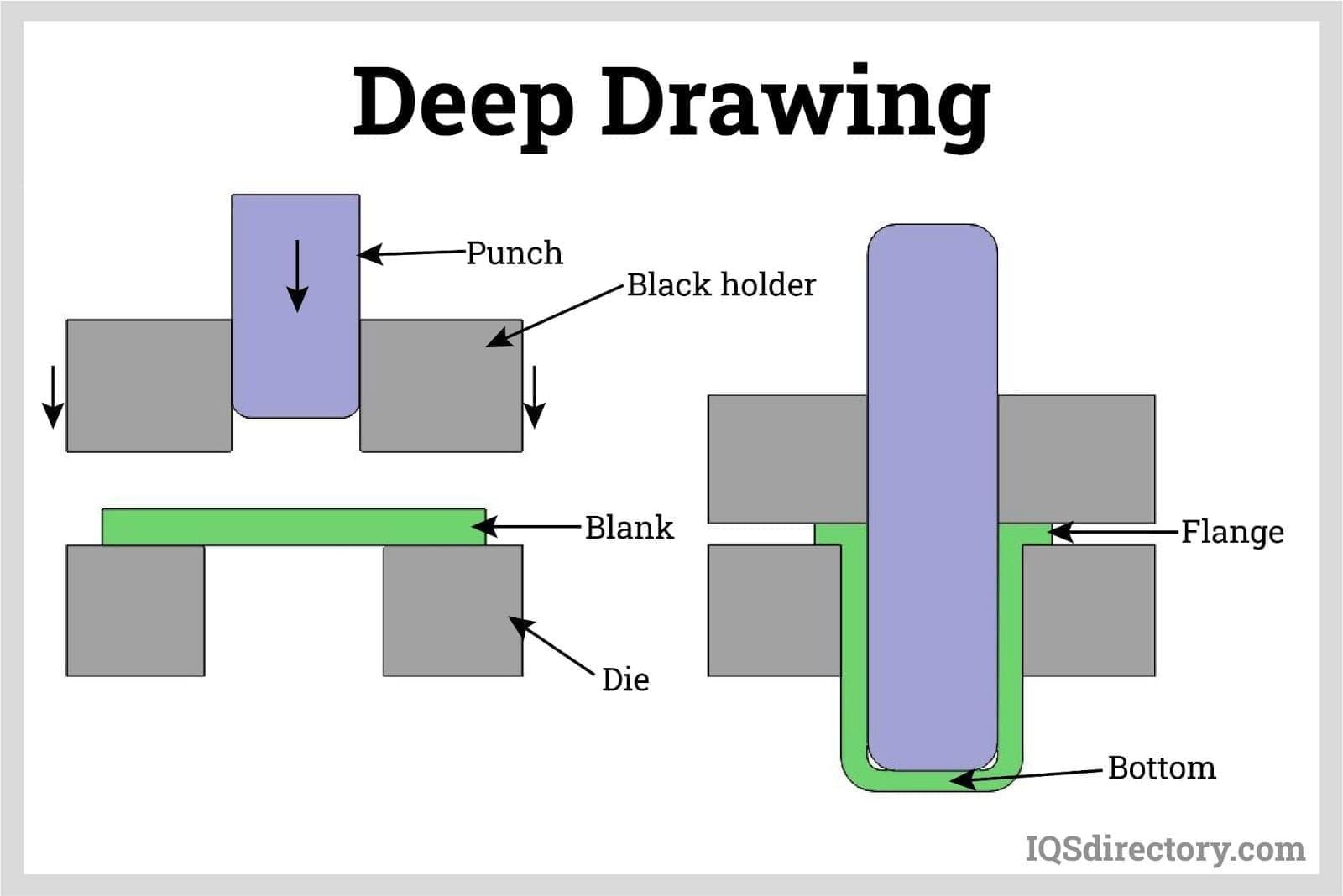

Deep Draw Stampings - The most prominent benefit is that the unit cost is decreased considerably when unit count increases. Custom tooling to meet your exact specifications. This is accomplished by drawing a flat metal blank into a die cavity (or several cavities in a series of steps) with a punch until the metal has been shaped into the desired form. In other words, once the die is created, mass production can create large volumes of products. Every deep draw metal stamping process starts with planning the part. Here at pmp, we tailor our deep drawing expertise in our metal forming technology to our customers’ needs & best practices. Web what is deep draw stamping? Commonly produced items from the deep draw stamping process include panels, tanks, containers, sinks, automotive parts and pots or. Cylindrical deep drawn aluminum cans are typical deep drawing applications. As industries evolve, the significance of this technique only grows, making it imperative for professionals and enthusiasts alike to grasp its nuances. Web prospect machine products deep draw metal stamping. Convert casting or plastic to metal stampings for cost saving | boehm pressed steel |. Web precision deep drawn stamping capabilities. Top deep drawn stamping services: Web deep drawn stampings & metal components | national die co. We can handle deep drawing in volumes ranging from a single prototype up to five million pieces or more. Web deep drawn stamping is typically used because it offers many advantages over traditional metal forming and manufacturing processes. Custom tooling to meet your exact specifications. Web what is deep draw stamping? We specialize in manufacturing complicated products, and will produce. Web deep drawn stampings & custom eyelets. In other words, once the die is created, mass production can create large volumes of products. This is accomplished by drawing a flat metal blank into a die cavity (or several cavities in a series of steps) with a punch until the metal has been shaped into the desired form. Web deep drawn. What are the types of deep drawing. Commonly produced items from the deep draw stamping process include panels, tanks, containers, sinks, automotive parts and pots or. Every deep draw metal stamping process starts with planning the part. Web precision deep drawn stamping capabilities. It involves drawing the metal sheet into a. Metal stampings made by thinking. Deep drawing is a type of metal forming process where parts are produced by punching sheet metal into a formed die. Here at pmp, we tailor our deep drawing expertise in our metal forming technology to our customers’ needs & best practices. Commonly produced items from the deep draw stamping process include panels, tanks, containers,. Web precision deep drawn stamping capabilities. The first station cuts a “blank” from the strip of material. Cylindrical deep drawn aluminum cans are typical deep drawing applications. Here at pmp, we tailor our deep drawing expertise in our metal forming technology to our customers’ needs & best practices. This is accomplished by feeding a coil of flat metal into a. Deep draw stamping, a cornerstone in the manufacturing world, has revolutionized the way we produce intricate metal components. Aqueous cleaning, deburring, heat treating, and passivation. The most prominent benefit is that the unit cost is decreased considerably when unit count increases. Web home » eyelets & deep drawn stampings » deep drawing. Commonly produced items from the deep draw stamping. Cylindrical deep drawn aluminum cans are typical deep drawing applications. National die company is proud to be an american manufacturer specializing in top quality, high volume deep drawn parts, eyelets, and components. Metal stampings made by thinking. We specialize in manufacturing complicated products, and will produce your small, medium, or large deep drawn stamping with the highest levels of precision. The first station cuts a “blank” from the strip of material. This is accomplished by drawing a flat metal blank into a die cavity (or several cavities in a series of steps) with a punch until the metal has been shaped into the desired form. We provide complex deep drawn metal stampings up to 16” in depth of draw. Web. Deep draw metal stamping is a processing method for making open hollow parts from flat material or hollow process parts by using a deep drawing die under the pressure of press. Bringing effective solutions to our customers through innovation and excellence. Web prospect machine products deep draw metal stamping. Web what can be made from deep draw stamping metal? At. Here at pmp, we tailor our deep drawing expertise in our metal forming technology to our customers’ needs & best practices. Top deep drawn stamping services: Web deep drawn stamping is highly versatile and can be used to create complex, detailed components with an exceptional degree of accuracy and repeatability. This is accomplished by feeding a coil of flat metal into a press with stations of tooling, each performing a repeating operation on the metal. Metal to rubber and metal to metal tooling for diaphragms. The three steps to deep draw metal stamping are as follows: Deep draw stamping, a cornerstone in the manufacturing world, has revolutionized the way we produce intricate metal components. Web prospect machine products deep draw metal stamping. Every deep draw metal stamping process starts with planning the part. Web deep drawn stamping is typically used because it offers many advantages over traditional metal forming and manufacturing processes. What’s more, deep drawn parts are exceptionally strong due to the extreme amount of compression exerted on the metal during the forming process. Web deep drawn stamping is a process of forming flat metal into a die to make precise, usually cylindrical shaped components. National die company is proud to be an american manufacturer specializing in top quality, high volume deep drawn parts, eyelets, and components. It involves drawing the metal sheet into a. What are the types of deep drawing. Often, it is the most effective way to form products that have unconventional or difficult geometries.

LESSONS LEARNED DEEP DRAW STAMPING Duggan Manufacturing

Deep Drawn Stamping Companies Deep Drawn Stamping Services

Metal Prototype Stamping Deep Drawn Prototypes Rapid Prototyping

Deep Draw Stamping D&H Industries

Deep Drawn Stamping Companies Deep Drawn Stamping Services

Deep Draw Metal Stampings & Formed Parts Hudson Technologies

Deep Draw Metal Stampings & Formed Parts Hudson Technologies

Deep Draw Stamping The Ultimate FAQ Guide CNstamping

Stamping Die Essentials Deep drawing Dynamic Die Supply

Deep Draw Metal Stamping Getting Started

Web Deep Drawn Stampings & Metal Components | National Die Co.

As Industries Evolve, The Significance Of This Technique Only Grows, Making It Imperative For Professionals And Enthusiasts Alike To Grasp Its Nuances.

In Other Words, Once The Die Is Created, Mass Production Can Create Large Volumes Of Products.

We Provide Complex Deep Drawn Metal Stampings Up To 16” In Depth Of Draw.

Related Post: