Deep Draw Process

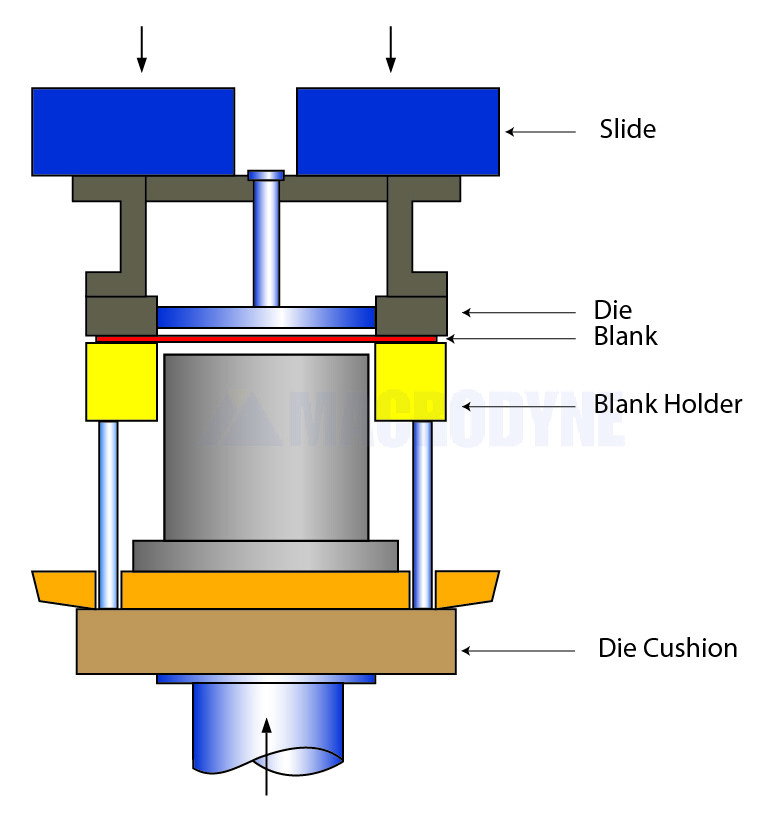

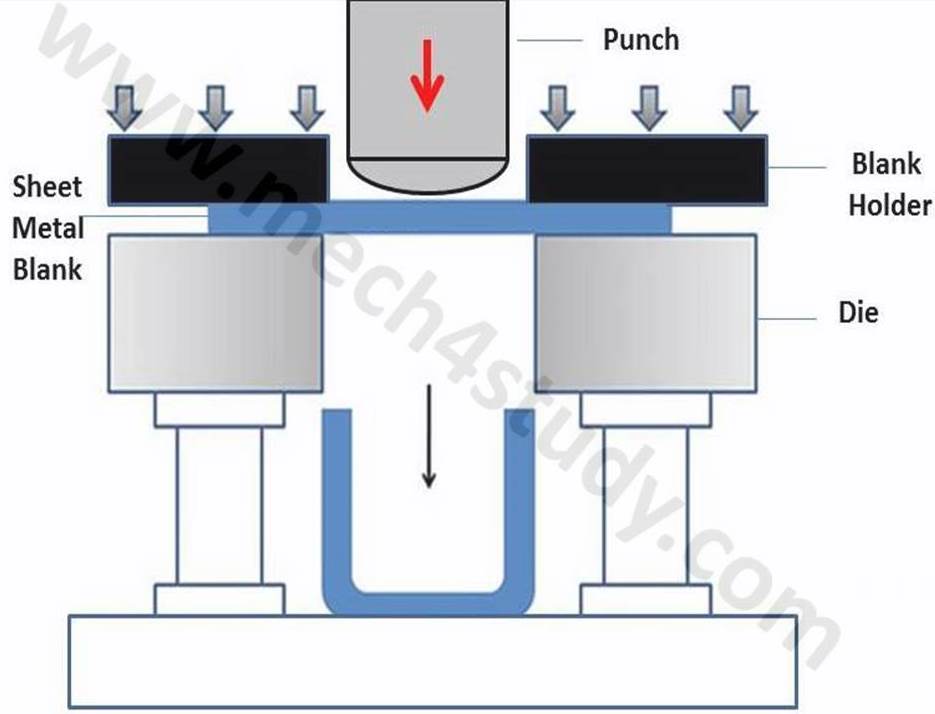

Deep Draw Process - Web table of contents. Web the deep draw process is necessary for parts with a depth that exceeds their diameter, like beverage cans, deep pans, assembly housings, and other containers. Web deep drawing specifically refers to the process of forming sheet metal into deep, hollow shapes by stretching the material into a die with a punch. Finite element analysis (fem) innovations in blankholder design for wrinkle mitigation. Explore the advantages, factors, and alternatives of this process for creating seamless, sheet metal parts with a depth greater than their radius. Examples of typical deep drawn components include cans, housings, and other containers. The three steps to deep draw metal stamping are as follows: This method can produce parts with significant depth relative to their diameter, such as: Every deep draw metal stamping process starts with planning the part design. And if the bhf is too large, cracks generally appear at. Understanding deep drawing wrinkle prediction. Finite element analysis (fem) innovations in blankholder design for wrinkle mitigation. Explore the advantages, factors, and alternatives of this process for creating seamless, sheet metal parts with a depth greater than their radius. The three steps to deep draw metal stamping are as follows: A blank piece of sheet metal is positioned over a die,. Web what is deep drawing? A blank piece of sheet metal is positioned over a die, and a punch is used to force the metal into the die and create a custom shape. Deep drawing is a sheet metal forming process by which a sheet metal blank is slightly clamped along its perimeter by a blank holder and radially drawn. Web in the deep drawing process, when the size of sheet metal, the die, the lubrication, the drawing speed, the temperature, etc., have been determined, the blank holder force (bhf) is the only controllable parameter in this stage. Web the deep draw process is necessary for parts with a depth that exceeds their diameter, like beverage cans, deep pans, assembly. Web deep drawing is a special process in sheet metal forming which is capable of forming many metallic parts and structures, and it covers a wide range of applications in packaging, automotive and aerospace industries. This operation entails a metal sheet being stretched over a die. Wrinkles will appear at the flange due to insufficient bhf. Process, diagram, advantages &. Web deep drawing is a metalworking process. Refining the deep drawing process. Web deep drawing specifically refers to the process of forming sheet metal into deep, hollow shapes by stretching the material into a die with a punch. Web the deep draw process is necessary for parts with a depth that exceeds their diameter, like beverage cans, deep pans, assembly. Web learn what deep drawing is, how it works, and when to use it. Process, diagram, advantages & applications. Deep drawing is a sheet metal forming process by which a sheet metal blank is slightly clamped along its perimeter by a blank holder and radially drawn into a forming die by use of a punch. With the punch, you push. Cups, pots, and automotive body panels. Web learn what deep drawing is, how it works, and when to use it. Web deep drawing specifically refers to the process of forming sheet metal into deep, hollow shapes by stretching the material into a die with a punch. Web learn the basics of deep drawing, a metalforming process that produces parts from. Cups, pots, and automotive body panels. Examples of typical deep drawn components include cans, housings, and other containers. The deep drawing process forms metal into complex shapes not possible with other forms of. This operation entails a metal sheet being stretched over a die. Deep drawing is a sheet metal forming process by which a sheet metal blank is slightly. Web learn the basics of deep drawing, a metalforming process that produces parts from flat blanks by pulling them into die cavities. And if the bhf is too large, cracks generally appear at. Web the deep drawing process saves you time and money through the efficient use of material and the ability to perform multiple, complex steps in one machine. The present study briefs about the current developments in the deep drawing process at the elevated temperature. Web table of contents. The three steps to deep draw metal stamping are as follows: It is poured into the shape of the die. Web learn the basics of deep drawing, a metalforming process that produces parts from flat blanks by pulling them. Web learn what deep drawing is, how it works, and when to use it. This method can produce parts with significant depth relative to their diameter, such as: This operation entails a metal sheet being stretched over a die. Initially, the blank is heated to plastic state and it is placed over the die as shown in figure 1. The three steps to deep draw metal stamping are as follows: Process, diagram, advantages & applications. Web table of contents. A blank piece of sheet metal is positioned over a die, and a punch is used to force the metal into the die and create a custom shape. Finite element analysis (fem) innovations in blankholder design for wrinkle mitigation. Web learn the basics of deep drawing, a metalforming process that produces parts from flat blanks by pulling them into die cavities. Understanding deep drawing wrinkle prediction. Find out how to calculate draw ratio, percent reduction, redraws and other factors that affect deep drawing. How to save money with deep draw. Web the deep drawing process saves you time and money through the efficient use of material and the ability to perform multiple, complex steps in one machine and in one process. Refining the deep drawing process. It is poured into the shape of the die.

Deep Draw Process for Precision Metal Components TransMatic TransMatic

Deep Drawing 101 Macrodyne

What is Deep Drawing Process? Mech4study

Deep drawing of sheet metal

What is Deep Drawing? Process, Diagram, Advantages & Applications

best deep drawing process, by chris YouTube

Deep Draw Process Precision Manufacturing Capabilities by PMP

What Is Involved in the Deep Drawn Manufacturing Process? Hudson

What Is Deep Drawing ? Working Of Deep Drawing Sheet Metal Processes

The Deep Draw Hydroforming Process & Advantages American Hydroformers

The Metal Goes Through A Plastic Deformation.

Explore The Advantages, Factors, And Alternatives Of This Process For Creating Seamless, Sheet Metal Parts With A Depth Greater Than Their Radius.

The Deep Drawing Process Forms Metal Into Complex Shapes Not Possible With Other Forms Of.

Web Deep Drawing Is A Metalworking Process.

Related Post: