Countersink Callout Drawing

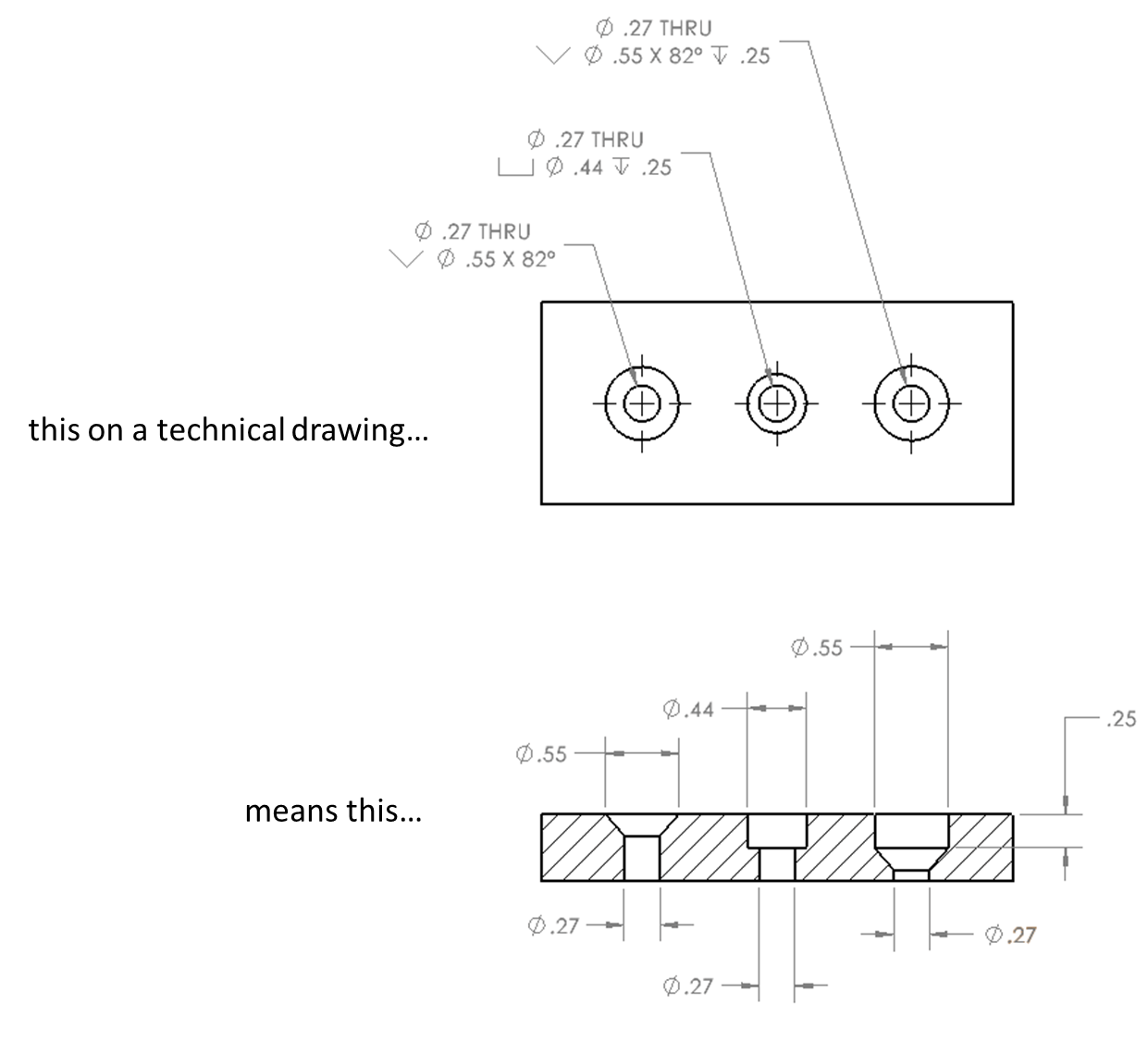

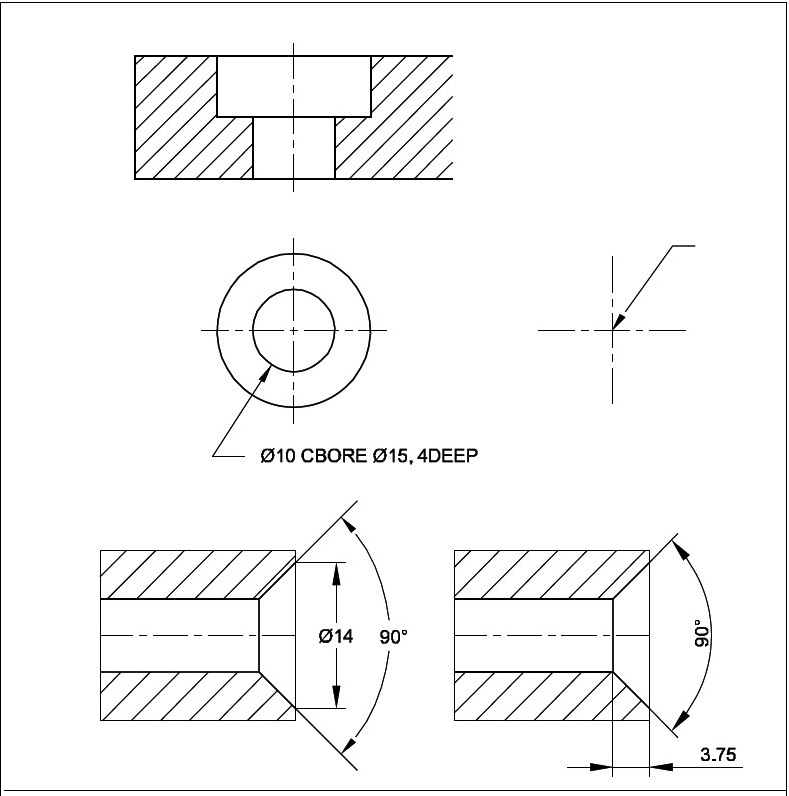

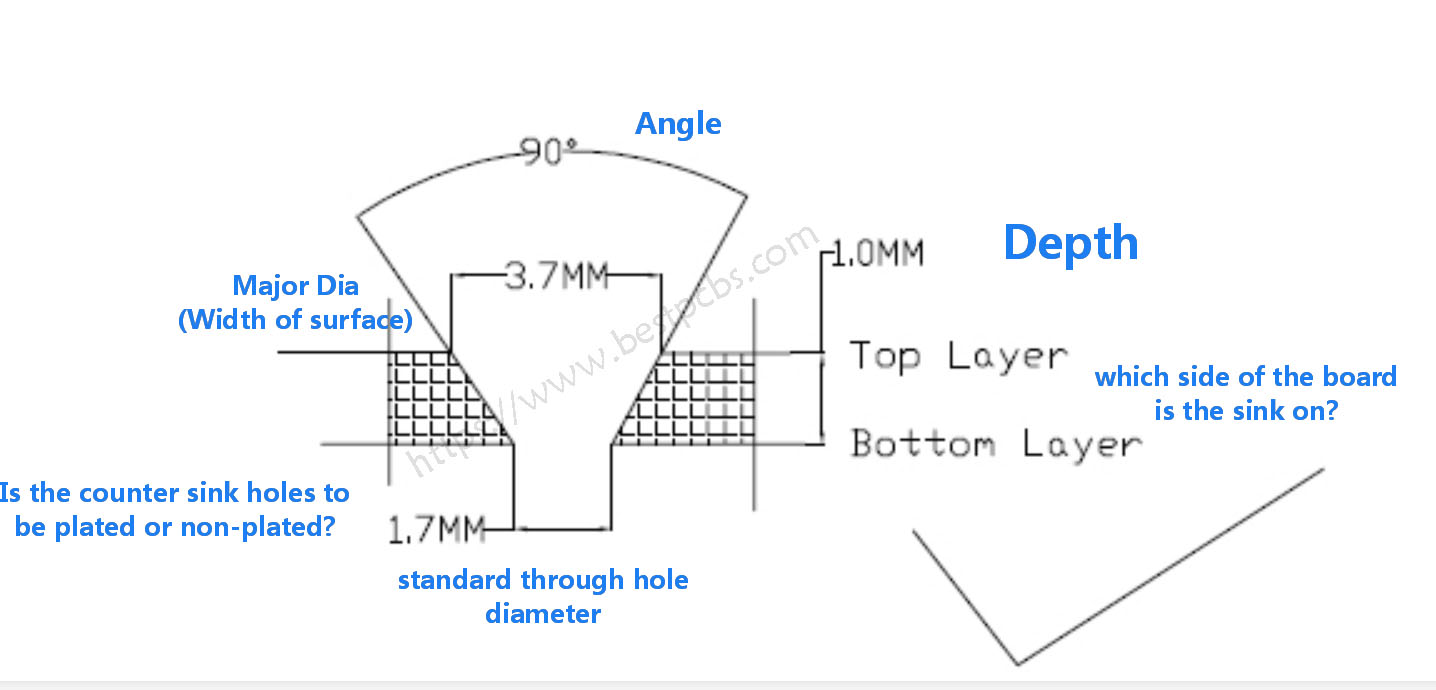

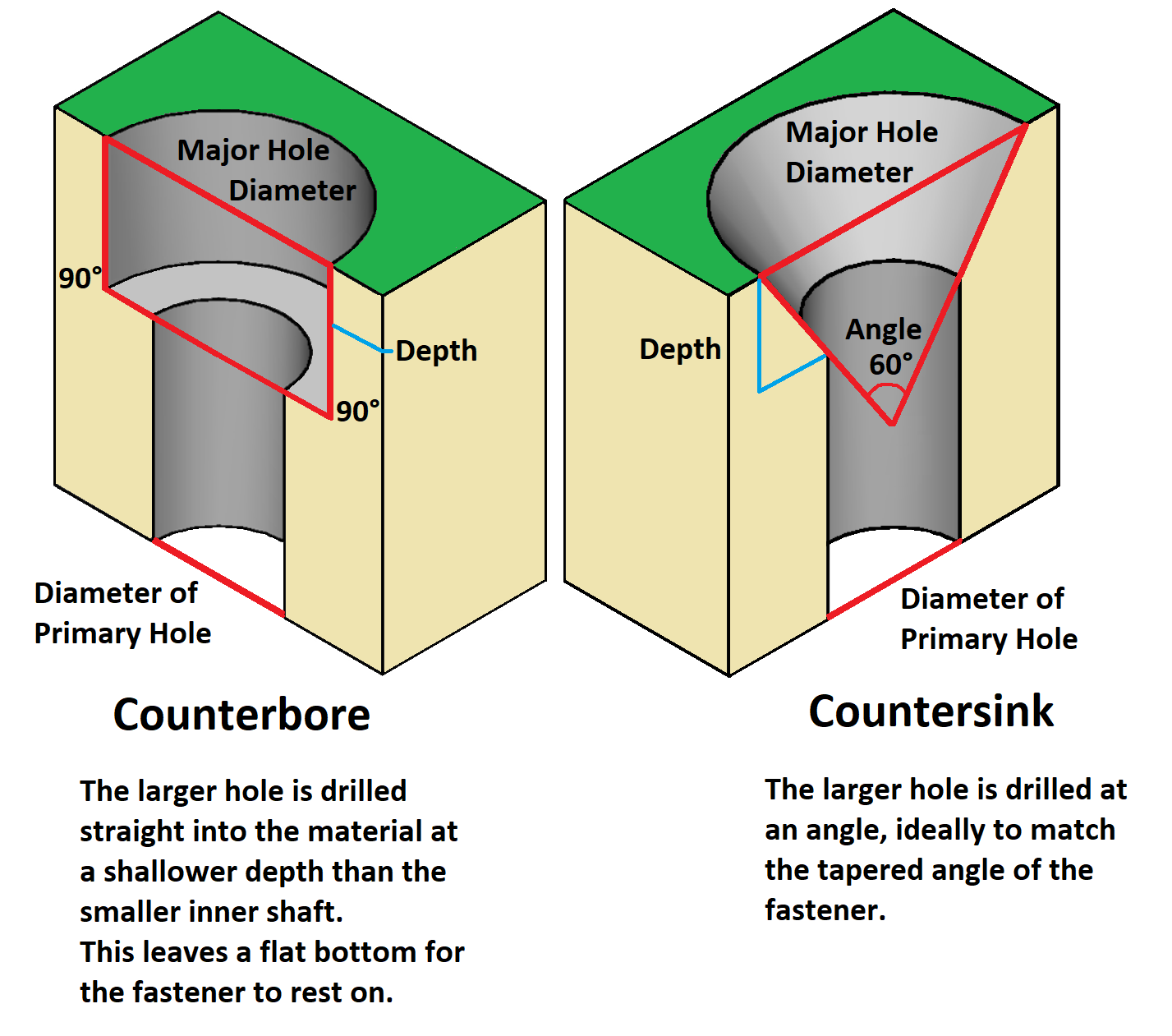

Countersink Callout Drawing - To add a hole callout: It is a conical hole cut into a material, allowing the screw. Web a countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used. Many of these elements are notational in nature. C read and interpret callouts for common machining. For instance, place the hole diameter and position. For a slotted hole, the diameter is usually given along. Click hole callout (annotation toolbar), or click insert > annotations > hole. Do not dimension to hidden lines/features. Web you can add hole callouts in standard drawing views and in section views. Web extracted to 2d drawings. You can edit the hole note after the hole feature is created: Draw the leader, or dimension line, with the arrow just touching the edge of the outer circle of the countersunk hole. The countersink symbol is used to indicate that a countersink hole feature is required. Web countersink callouts:when creating technical drawings or specifications,. Web you can add hole callouts in standard drawing views and in section views. Web a countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used. A countersink hole is one in which the outer edge of the hole has been opened up. Web properties tab > rename hole to countersink 4. You can edit the hole note after the hole feature is created: Place all of the dimensions for one feature in one view if possible. To add a hole callout: Web countersink callouts:when creating technical drawings or specifications, countersink holes can be indicated using callouts that provide specific details such as. Some examples include thread specifications, surface finishes, surface quality, and dimension tolerances. It is a conical hole cut into a material, allowing the screw. For a slotted hole, the diameter is usually given along. Place all of the dimensions for one feature in one view if possible. Web countersink callouts:when creating technical drawings or specifications, countersink holes can be indicated. This is a complete guide to the types of holes found in machining. Web you can add hole callouts in standard drawing views and in section views. Web this unit will additional processes such as counterbores and help provide you the knowledge needed for this. Web these callouts use standard symbols for number of places, diameter, depth, counterbore, and countersink.. A countersink hole is one in which the outer edge of the hole has been opened up to a conical entry. Web units of measurement. Click hole callout (annotation toolbar), or click insert > annotations > hole. To add a hole callout: Web properties tab > rename hole to countersink 4. The measurement units will often. The purpose of a countersink is to. Draw the leader, or dimension line, with the arrow just touching the edge of the outer circle of the countersunk hole. For a slotted hole, the diameter is usually given along. Web you can add hole callouts in standard drawing views and in section views. C read and interpret callouts for common machining. Draw the line radially, so that it points toward the center. For a symmetric part, it is only necessary to dimension to one side of the center line of. Web countersink callouts:when creating technical drawings or specifications, countersink holes can be indicated using callouts that provide specific details such as the angle,.. C read and interpret callouts for common machining. For ansi/imperial fasteners, it is commonly. To add a hole callout: Web properties tab > rename hole to countersink 4. Web 15 feb 06 15:23. Web units of measurement. Check the add a note check box to create the hole note. For instance, place the hole diameter and position. Many of these elements are notational in nature. Draw the line radially, so that it points toward the center. For instance, place the hole diameter and position. So they give the angle and the. Web key steps in calling out countersink drawings. It is a conical hole cut into a material, allowing the screw. In this guide you’ll learn: This is a complete guide to the types of holes found in machining. The purpose of a countersink is to allow a fastener, typically a. The purpose of a countersink is to. Web units of measurement. Web when the hole tab is open, click the note tab. Do not dimension to hidden lines/features. An arc length is dimensioned using the arc length symbol. The countersink symbol is used to indicate that a countersink hole feature is required. For a slotted hole, the diameter is usually given along. For ansi/imperial fasteners, it is commonly. Click hole callout (annotation toolbar), or click insert > annotations > hole.

The Benefits of Countersinking SendCutSend

PPT Chapter 10 cont. PowerPoint Presentation, free download ID1984589

ENGINEERING DRAWING Dimensioning

What’s the Countersink and counter bore on a PCB drawing?

SOLIDWORKS 2018 Advanced Hole & Callout Tutorial Innova Systems

Types of Holes The Complete Guide The Engineer's Bible

PCB Hole Types Counterbore vs Countersink ABL Circuits

SOLIDWORKS 2018 Advanced Hole & Callout Tutorial Innova Systems

Countersink Example3 OER

PLTW IED 5.5 Countersink in Fusion 360 YouTube

C Read And Interpret Callouts For Common Machining.

For A Symmetric Part, It Is Only Necessary To Dimension To One Side Of The Center Line Of.

The Callout Is As Follows:

Green Check To Accept 5.

Related Post: